Adirondack case guy

Well-known Member

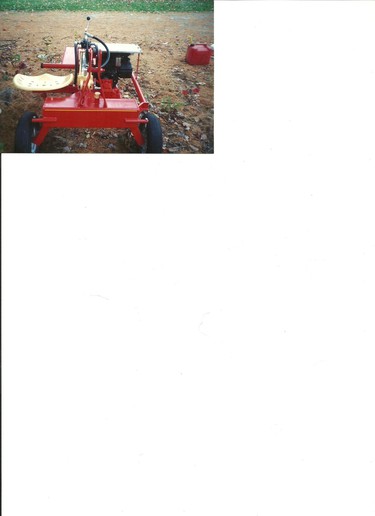

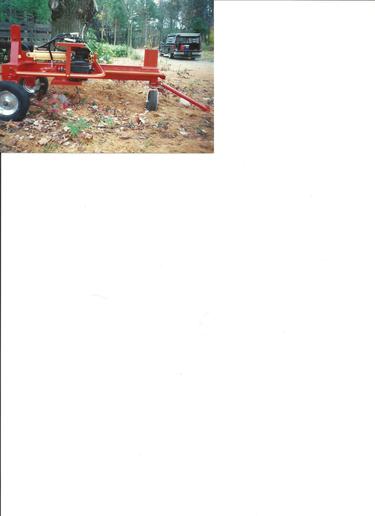

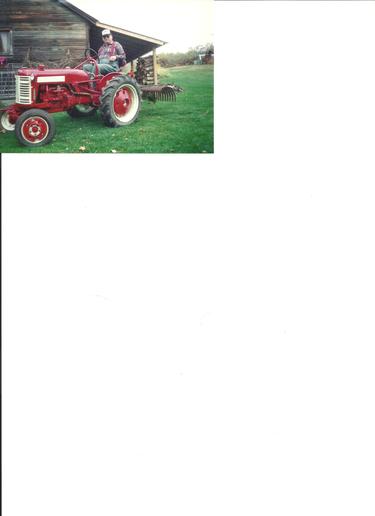

If this splitter could talk or tell me how many blocks of wood it split and I had a nickel for every one it did I wouldn't be working now. When we ran our Case dealership we sold these American Woodspliters, built in Black River NY. They made many models from basic self contained units with a 5HP B&S to 20HP custom units. Our most popular unit was the vertical 3pt hitch unit that utilized the tractor hyds. This basic 1978+- model had 2 wheelbarrow wheels and a simple tab on the end to drop a pin into to transport it behind a tractor. Back in that time I clear cut some wooded area on the farm to straighten out some feilds. Logs went to market and fire wood was sold locally. My kids were at working age and we worked hard on weekends, but they shared in the income from their hard work and today they look back on those times as having fun, rather than work. We totally used up 1 B&S motor, Had one which didn't survive a crash after falling out of a PU, OOPS. In 1990 I reconstructed it. One had to litterally work on his/her knees to operate it. (back pain) I welded the raised axle struts on the rear and a caster on a strut on the front. I also welded the A frame for the 3pt on the oil tank, plus I incorperated an easily detachable toung on the front so a tractor or 4wheeler could tow it. Makes it easy to move in garage when not in use also, and now high enough to reduce bending while splitting. The seat was incorperated for a very special Family friend that loved to be a part of all our activities. He is pictured in the last pic and now enjoying things in the world beyond.