Anonymous-0

Well-known Member

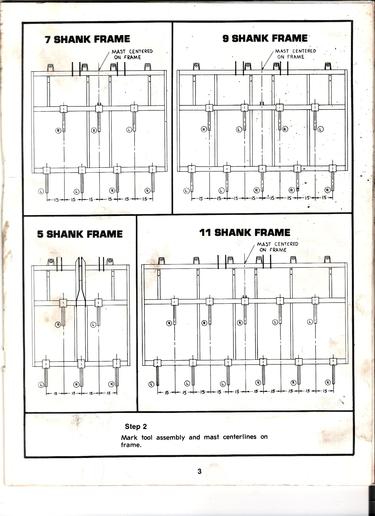

We recently purchased a white 435, 9 shank 3 bar, disc chisel. We dropped 2 shanks to make it a 7. I believe the previous owner mixed and matched the right and left hand shovels and now i do not know how it should be set-up. I know i need 4 right hand shovels and three left hand shovels.

The front bar has two shanks, the middle bar has two shanks, and the back bar has three shanks.

Can anyone tell me where the left and right hand shovels should go?

Thanks.

The front bar has two shanks, the middle bar has two shanks, and the back bar has three shanks.

Can anyone tell me where the left and right hand shovels should go?

Thanks.