alabamafrog

Well-known Member

I lost the rear ring gear in my truck coming home from a show yesterday. Looks like it sheared two of the gear teeth completely off in two different spots on the ring gear and sent them through the cover. Anyone got any ideas on the best way to fix this and maybe upgrade so it don’t happen again. I would love to upgrade to a limited slip or posi unit while I’m at it but money is real tight right now. I think it is a Ford 10.5” diff, looks like I can get a ring and pinion set for $255 and a installation kit for another $290 so that would be $550 just for parts.

Anyone got any better ideas or options I could consider?

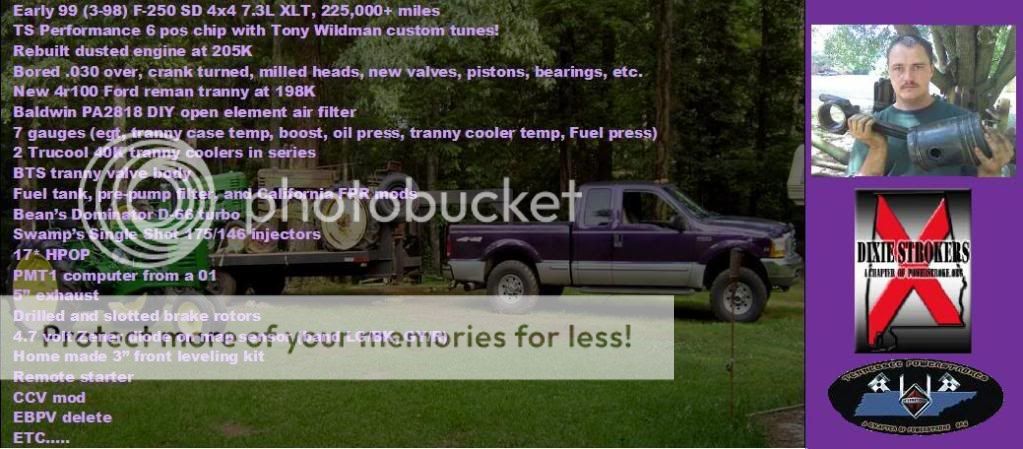

Here is a pic of the carnage;

Anyone got any better ideas or options I could consider?

Here is a pic of the carnage;