SouthernFarmall

Member

Hi, everyone! I am working on solving a bad oil leak on my

gas IH 674. Engine oil is dripping from the bell housing.

I will go through between one and two quarts of oil per day.

I have the tractor split, thinking that the problem would

be the rear main seal. However, this tractor does not have

a rear main seal that is held within a retainer like the

diesel models.

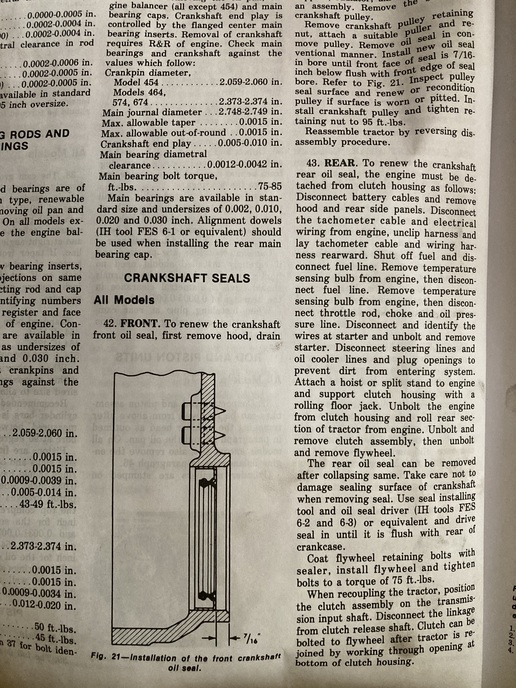

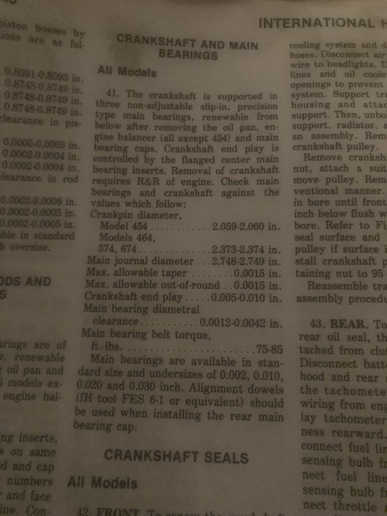

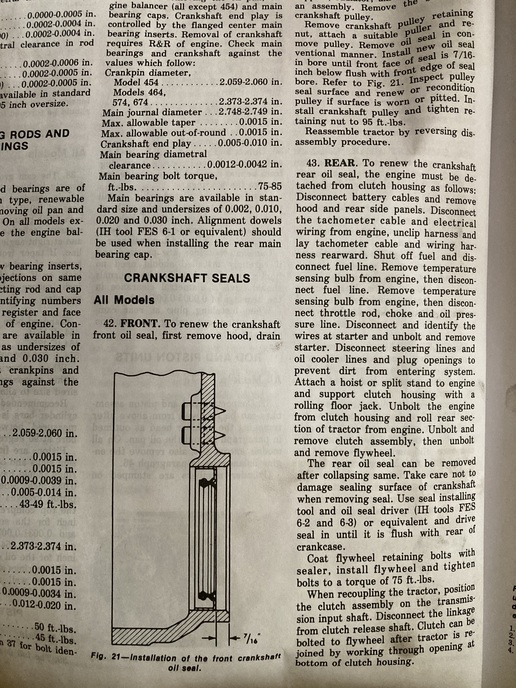

How am I supposed to remove the rear main seal? My

shop manual goes through a long explanation of how to

split the tractor and then simply says that the rear oil seal

can be removed after collapsing same. What does that

mean?

Also, is there anything else that I should be looking at

that could be causing this leak? Could it be a leak

between the oil pan and the engine block or rear main

bearing caps? How would I go about fixing that, if so?

I am going to try to post a picture of the rear main seal in

my tractor and a picture of what my shop manual says.

Any help is appreciated! Thanks!

gas IH 674. Engine oil is dripping from the bell housing.

I will go through between one and two quarts of oil per day.

I have the tractor split, thinking that the problem would

be the rear main seal. However, this tractor does not have

a rear main seal that is held within a retainer like the

diesel models.

How am I supposed to remove the rear main seal? My

shop manual goes through a long explanation of how to

split the tractor and then simply says that the rear oil seal

can be removed after collapsing same. What does that

mean?

Also, is there anything else that I should be looking at

that could be causing this leak? Could it be a leak

between the oil pan and the engine block or rear main

bearing caps? How would I go about fixing that, if so?

I am going to try to post a picture of the rear main seal in

my tractor and a picture of what my shop manual says.

Any help is appreciated! Thanks!