super99

Well-known Member

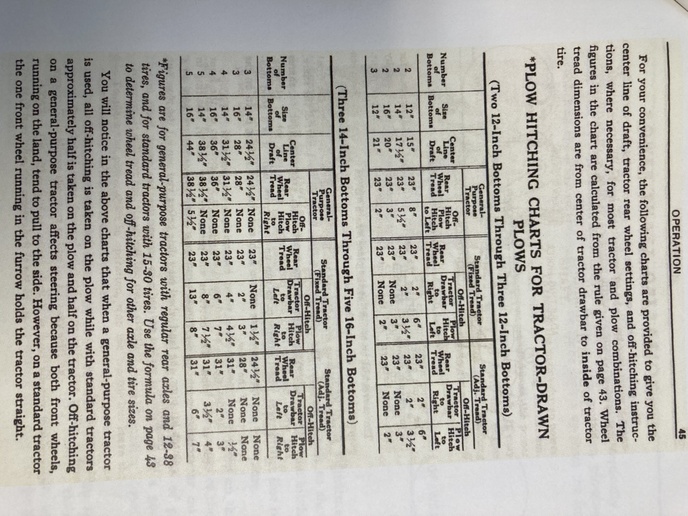

When I pull my Oliver 4240 3 bottom plow I have to move the drawbar 2 holes to the land side to make the plow run in the furrow, I am trying to move the furrow wheel on my Oliver 1550 in so I dont have to move the drawbar when plowing. I have operators manual but it doesnt say anything about where to set rear tractor wheel. When the drawbar is straight it measures 30 inches from center of drawbar to inside edge of the tire

When I move the drawbar 2 holes to the right, it measures 25 1/2 inches to the tire.

The plow measures 28 inches from center of drawbar to the furrow wheel

I think I need to move the tractor wheel in about 5 inches to make everything line up. Anyone know where the furrow wheel should be set to line everything up? The wheel hub U bolts are rusted in tight and dont want to loosen up so I can move the hub.

I got the wheel off tonight and will try heat and beat again tomorrow .

When I move the drawbar 2 holes to the right, it measures 25 1/2 inches to the tire.

The plow measures 28 inches from center of drawbar to the furrow wheel

I think I need to move the tractor wheel in about 5 inches to make everything line up. Anyone know where the furrow wheel should be set to line everything up? The wheel hub U bolts are rusted in tight and dont want to loosen up so I can move the hub.

I got the wheel off tonight and will try heat and beat again tomorrow .