Geo-TH,In

Well-known Member

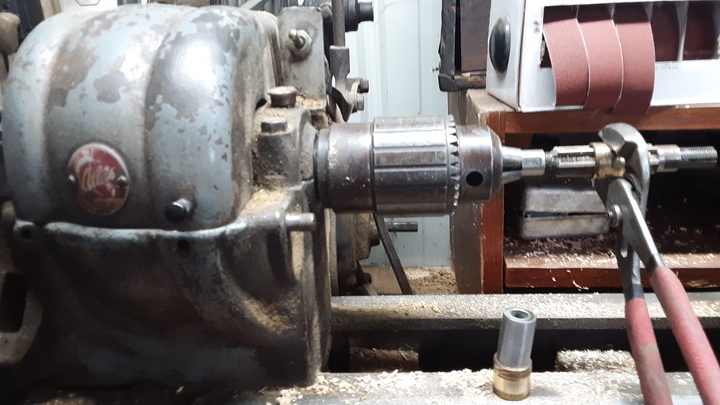

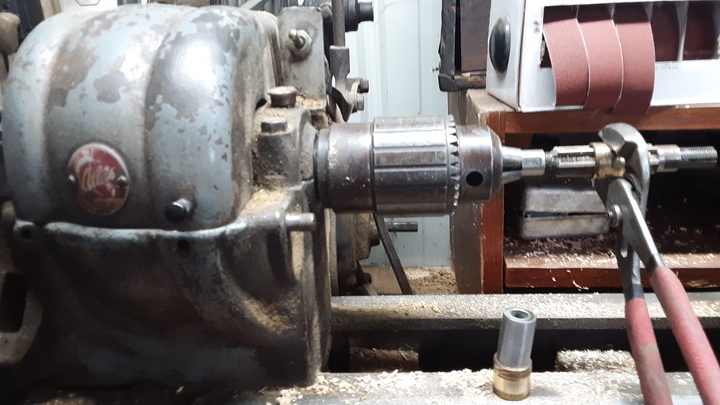

The drive belt idler pulley is attached to a swing arm. The swing arm's plastic bushings were shot. So I made my own bushings out of brass bushings.

The original kevlar drive belt is 1/2 x 102.5.

I ordered a 5/8 x 102.5 kevlar drive belt. The last pic is the transmission pulley. I think there is enough room to use a fatter belt.

Thanks to the person that said check the idler pulley which I had replaced with a steel pulley. The plastic pulley was damaged. Now I know why the plastic pulley had a problem. The pulley was tilted and the old belt got pinched, friction melting the plastic pulley.

I rarely use my atlas lathe, which is my age, and adjustable reams.

I was happy to have them so I could make a special bushing.

The original kevlar drive belt is 1/2 x 102.5.

I ordered a 5/8 x 102.5 kevlar drive belt. The last pic is the transmission pulley. I think there is enough room to use a fatter belt.

Thanks to the person that said check the idler pulley which I had replaced with a steel pulley. The plastic pulley was damaged. Now I know why the plastic pulley had a problem. The pulley was tilted and the old belt got pinched, friction melting the plastic pulley.

I rarely use my atlas lathe, which is my age, and adjustable reams.

I was happy to have them so I could make a special bushing.