To all: A question for you all. I've always just followed some ones posted wiring diagraph and it has always worked. I've always placed a resister between the coil and the distributor. my understanding was that it knocked down the voltage/amperage?? going into the existing 6 volt distributor. If that is the case does one need a 12 volt coil in the conversion, and if you use the existing 6volt coil do you need a resistor. Any explanation needs to be simple and straight forward as electrical stuff is not in my wheel house. Like I said, I've always just followed the directions and used whatever the diagraph called for. Thanks, I hope to say good by to my last 6 volt battery. Please don't chastise me for converting, I'm done with 6 volt generators regulators and batteries. gobble

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Thread starter tomturkey

- Start date

f you use an honest 12v coil, no resistor needed.. Resistor needed to reduce coil current if 6v coil needed. Not real likely that you saw diagram with resistor between coil and distributor. The correct placement is between ignition switch and coil. Between coils & distributor will run, but spark is likely reduced a bit. Observe polarity markings on coil (+/-) for same reason, i.e., slight reduction in spark, but will run.(quoted from post at 17:30:48 08/16/23) To all: A question for you all. I've always just followed some ones posted wiring diagraph and it has always worked. I've always placed a resister between the coil and the distributor. my understanding was that it knocked down the voltage/amperage?? going into the existing 6 volt distributor. If that is the case does one need a 12 volt coil in the conversion, and if you use the existing 6volt coil do you need a resistor. Any explanation needs to be simple and straight forward as electrical stuff is not in my wheel house. Like I said, I've always just followed the directions and used whatever the diagraph called for. Thanks, I hope to say good by to my last 6 volt battery. Please don't chastise me for converting, I'm done with 6 volt generators regulators and batteries. gobble

JMOR, I just checked my diagraph from my files and you are absolutely correct, resistor between ign switch and coil. you are also correct that it will run with

the resistor between the coil and the distributor as I have two tractors set up that way. My dyslexia must have been kicking in and I just copied what I had on

another tractor. What is the resistor doing to the voltage from the ign to the coil? My misunderstanding is that the points and condenser were set up for 6

volts, so as not to burn up points or condensers we used the resistor. Like I said my misunderstanding. If its been awhile for me sometimes I must go back to

the beginning to understand what I am doing, and its been awhile. thanks for you help. gobble

the resistor between the coil and the distributor as I have two tractors set up that way. My dyslexia must have been kicking in and I just copied what I had on

another tractor. What is the resistor doing to the voltage from the ign to the coil? My misunderstanding is that the points and condenser were set up for 6

volts, so as not to burn up points or condensers we used the resistor. Like I said my misunderstanding. If its been awhile for me sometimes I must go back to

the beginning to understand what I am doing, and its been awhile. thanks for you help. gobble

Hi Tom, your good question:

If that is the case does one need a 12 volt coil in the conversion, and if you use the existing 6volt coil do you need a resistor. Any explanation needs to be simple and straight forward

its been answered before by myself and others so I will just give you some basics, SIMPLE AND STRAIGHT FORWARD AS YOU ASKED and ONLY to your question

If its a 12 volt tractor you can use EITHER A) A full true 12 volt rated coil NO BALLAST REQUIRED orrrrrrrrrr B) The old 6 volt coil PLUS an inline series voltage dropping (12 down to 6) Ballast Resistor placed between the ignition switch output and coils input (NOT elsewhere is my choice) .. That way it drops 6 volts leaving 6 volts for a 6 volt coil EASY PEASEY works either way.

NOTE match the coil polarity to that of the tractor.

Hey this YOUR tractor YOUR money YOUR choice you get no argument from me

Post back any more questions, I purposely DID NOT talk about things you didn't ask.

John T

If that is the case does one need a 12 volt coil in the conversion, and if you use the existing 6volt coil do you need a resistor. Any explanation needs to be simple and straight forward

its been answered before by myself and others so I will just give you some basics, SIMPLE AND STRAIGHT FORWARD AS YOU ASKED and ONLY to your question

If its a 12 volt tractor you can use EITHER A) A full true 12 volt rated coil NO BALLAST REQUIRED orrrrrrrrrr B) The old 6 volt coil PLUS an inline series voltage dropping (12 down to 6) Ballast Resistor placed between the ignition switch output and coils input (NOT elsewhere is my choice) .. That way it drops 6 volts leaving 6 volts for a 6 volt coil EASY PEASEY works either way.

NOTE match the coil polarity to that of the tractor.

Hey this YOUR tractor YOUR money YOUR choice you get no argument from me

Post back any more questions, I purposely DID NOT talk about things you didn't ask.

John T

The resistor is decreasing the voltage to the coil. The goal is to get the voltage at the 6V coil to be approximately half of the 12 volts of the battery. This depends on what the DC resistance is of the coil. As Geo mentioned, the ohms value of the resistor is important as well as the wattage rating. Sorry if I'm getting too deep with this. I won't go any deeper.

redforlife

Well-known Member

12 volt battery and no resister and 12 volt converted coil/distributor.

Or

12 volt battery, a resister, and coil/distributor left as 6v.

I put resister between kill switch and coil.

If you leave distributor as 6v, and go to negative ground 12v battery, hook wires up accordingly on coil. Which basically means switch them around. Coil terminals should specify + and - . So naturally wires need to be swapped there if you change grounds of the system.

Or

12 volt battery, a resister, and coil/distributor left as 6v.

I put resister between kill switch and coil.

If you leave distributor as 6v, and go to negative ground 12v battery, hook wires up accordingly on coil. Which basically means switch them around. Coil terminals should specify + and - . So naturally wires need to be swapped there if you change grounds of the system.

caterpillar guy

Well-known Member

If he just buys a resistor for an old Chrysler product from the 60's it will work just fine and is already set up for the job. No fooling around with OHM meters for it.

grandpa Love

Well-known Member

I use a coil from Napa. 12 volt , no external resistor required.

grandpa Love

Well-known Member

The coil we use on 12 volt conversion is written on the barn wall....

BarnyardEngineering

Well-known Member

- Location

- Rochester, NY

tom, in a simple DC circuit the location of the resistor doesn't matter. It achieves the same result.

Also, distributors are voltage-agnostic. There is nothing you need to do to the distributor itself to "convert" from 6V to 12V. The wire from the coil to the distributor is just so the distributor can "ground" the coil through the points, completing the circuit and causing it to charge for the next spark.

This post was edited by BarnyardEngineering on 08/17/2023 at 06:21 am.

Also, distributors are voltage-agnostic. There is nothing you need to do to the distributor itself to "convert" from 6V to 12V. The wire from the coil to the distributor is just so the distributor can "ground" the coil through the points, completing the circuit and causing it to charge for the next spark.

This post was edited by BarnyardEngineering on 08/17/2023 at 06:21 am.

rvirgil_KS

Well-known Member

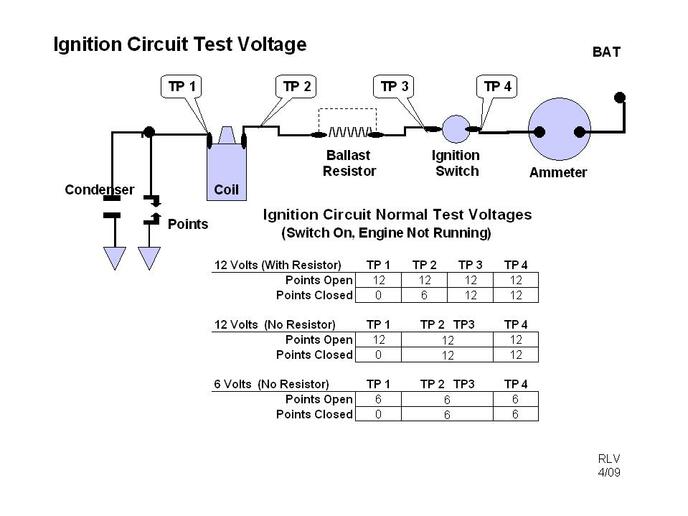

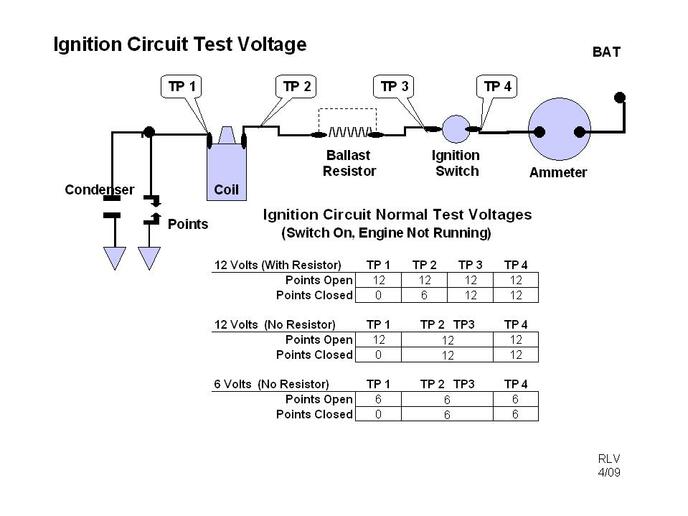

Here is a diagram that may help you better understand the question.

The points and the coil do not care if circuit is fed from a 6 or 12 volt battery. The points and coil want a near constant AMPS (usually about 4 amps).

Ohms law states that the current equals voltage divided by resistance.

6 volt coils are about 1 1/2 ohm resistance across primary, direct 12 /volt no resistor required coils are about 3 ohms.

In a 6 volt system 6 volts divided by 1 1/2 ohms equals 4 amps.

If you double the voltage to 12 volts you will need to double the resistance to 3 ohms to maintain the 4 amps. This can be done by adding a 1 1/2 ohm resistor or changing to a 3 ohm coil.

These voltage, current, and resistance values are nominal and will vary slightly in real life.

The 3 ohm direct 12 volt coil has the internal resistance determined by type of wire and number of turns in the coil. It does not have a separate resistor in series with the winding inside the coil can.

The points and the coil do not care if circuit is fed from a 6 or 12 volt battery. The points and coil want a near constant AMPS (usually about 4 amps).

Ohms law states that the current equals voltage divided by resistance.

6 volt coils are about 1 1/2 ohm resistance across primary, direct 12 /volt no resistor required coils are about 3 ohms.

In a 6 volt system 6 volts divided by 1 1/2 ohms equals 4 amps.

If you double the voltage to 12 volts you will need to double the resistance to 3 ohms to maintain the 4 amps. This can be done by adding a 1 1/2 ohm resistor or changing to a 3 ohm coil.

These voltage, current, and resistance values are nominal and will vary slightly in real life.

The 3 ohm direct 12 volt coil has the internal resistance determined by type of wire and number of turns in the coil. It does not have a separate resistor in series with the winding inside the coil can.

Wore out and Jessie, I looked but cant find it now I will try again later. The

article its tests and results showed why the ballast resistor should be placed BETWEEN

IGNITION SWITCH AND THE COILS INPUT. If I find it I will let yall know, seems like it

had to do in part with the coils ringing and coil/condensor current as the condensor

discharged and recharged BUT I FORGET no warranty lol

John T still ever curious yet retired EE

article its tests and results showed why the ballast resistor should be placed BETWEEN

IGNITION SWITCH AND THE COILS INPUT. If I find it I will let yall know, seems like it

had to do in part with the coils ringing and coil/condensor current as the condensor

discharged and recharged BUT I FORGET no warranty lol

John T still ever curious yet retired EE

would like to see it. I had a distributor set up on bench driven by a variable speed motor and did many experiments with different coils and different connection configurations and concluded that placement may matter theoretically , but not in actuality (resulting spark).(quoted from post at 11:53:42 08/17/23) Wore out and Jessie, I looked but cant find it now I will try again later. The

article its tests and results showed why the ballast resistor should be placed BETWEEN

IGNITION SWITCH AND THE COILS INPUT. If I find it I will let yall know, seems like it

had to do in part with the coils ringing and coil/condensor current as the condensor

discharged and recharged BUT I FORGET no warranty lol

John T still ever curious yet retired EE

Similar threads

- Replies

- 23

- Views

- 571

We sell tractor parts! We have the parts you need to repair your tractor - the right parts. Our low prices and years of research make us your best choice when you need parts. Shop Online Today.

Copyright © 1997-2024 Yesterday's Tractor Co.

All Rights Reserved. Reproduction of any part of this website, including design and content, without written permission is strictly prohibited. Trade Marks and Trade Names contained and used in this Website are those of others, and are used in this Website in a descriptive sense to refer to the products of others. Use of this Web site constitutes acceptance of our User Agreement and Privacy Policy TRADEMARK DISCLAIMER: Tradenames and Trademarks referred to within Yesterday's Tractor Co. products and within the Yesterday's Tractor Co. websites are the property of their respective trademark holders. None of these trademark holders are affiliated with Yesterday's Tractor Co., our products, or our website nor are we sponsored by them. John Deere and its logos are the registered trademarks of the John Deere Corporation. Agco, Agco Allis, White, Massey Ferguson and their logos are the registered trademarks of AGCO Corporation. Case, Case-IH, Farmall, International Harvester, New Holland and their logos are registered trademarks of CNH Global N.V.

Yesterday's Tractors - Antique Tractor Headquarters

Website Accessibility Policy