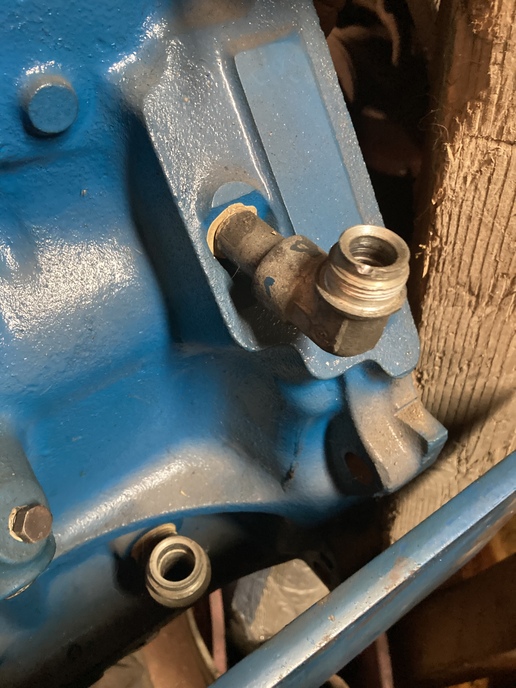

hey, im planning on putting a turbo on an International 574 1973 but i have a few questions regarding the oiling system to the turbo, im wondering where i should hook up the oil feed line from the engine, ive

seen some videos where there is a plug on the side of the block and they hook it up directly to that but i wanna make sure it has pressure and if it disturbs the oil going in that passage around the engine so

it doesn't run dry. My second question is where should i route the oil drain line, ive also seen some videos where they drill and tap a hole on the side of the valve cover but im not sure if that is correct,

wont it be alot of excessive oil that has to go back to the oil pan? or should i route it to the oil pan or close enough so it drains directly down in the oil pan?

after all i want to keep this engine running for many years

any help will be appreciated

Thanks.

seen some videos where there is a plug on the side of the block and they hook it up directly to that but i wanna make sure it has pressure and if it disturbs the oil going in that passage around the engine so

it doesn't run dry. My second question is where should i route the oil drain line, ive also seen some videos where they drill and tap a hole on the side of the valve cover but im not sure if that is correct,

wont it be alot of excessive oil that has to go back to the oil pan? or should i route it to the oil pan or close enough so it drains directly down in the oil pan?

after all i want to keep this engine running for many years

any help will be appreciated

Thanks.