Nemesismotors13

New User

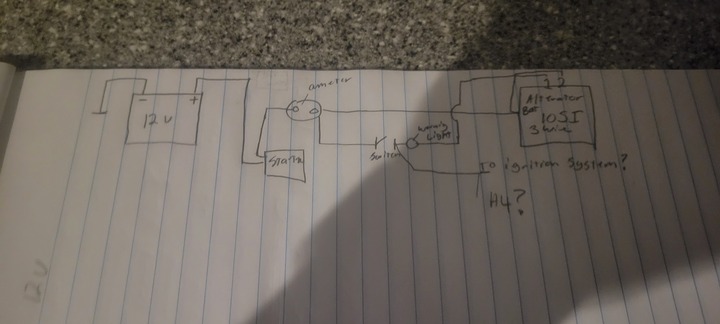

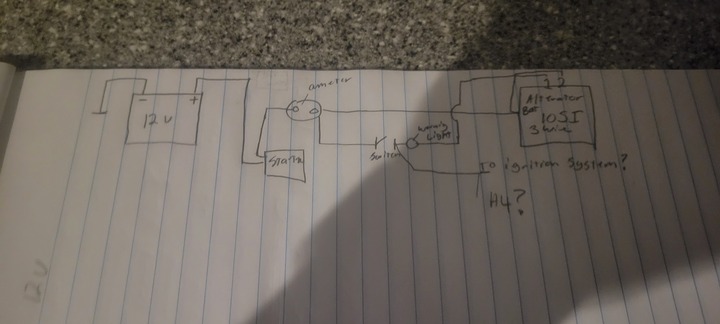

hey guys just an update on what is becoming more of a parts expedition than a refurbish. Started tear down a few weeks back and decided that I am going to work on the motor first and work my way back because fortunately besides the rear main it is not leaking and I am not equipped to split it yet so I am going to to an in frame rebuild and the body work. I am currently trying to work out the 12v conversion I am going to get a brillman kit and wiring harness but I do not know if I can keep my H4 magneto that I just rebuilt. I drew out what I think the wireing should look like. My question is the hot wire that goes to the coil can I use it as the hot wire for ignition coil that comes on the brillman harness to the magneto or will I need to create a ground for it? I really do not know a whole lot about 6 to 12 v conversions except that I know i have to change bulbs and ballast resistors on swithces and what not. Is there any one running a 12v conversion with an H4 Magneto?