1939farmall

Member

Let me say first off I believe the problem is 70 percent my own

ignorance and 30 percent worn or out of adjustment machine. This is

a 1950s? David Bradly sickle mower. Looks like model number 917

5821.

Id love to get this back in working condition but if nothing else I have

to learn how to properly maintain a sickle mower. Heres the issue. I

was using it at the end of summer to mow our pasture. It kept

plugging up. I kept clearing it and trying again. I thought I had it ready

to go. Obviously not! I quit when the clutch was just free spinning. I

was pulling it with a Farmall M in 1st gear open throttle.

Now that I have it in the shop I can turn the PTO by hand and

everything appears to be working. Could I have just gotten the belt

hot and it slipped? The clutch appears to use 4 keys that it engages

on but without disassembly they appear to be intact. Also it appears

the bar is out of adjustment.

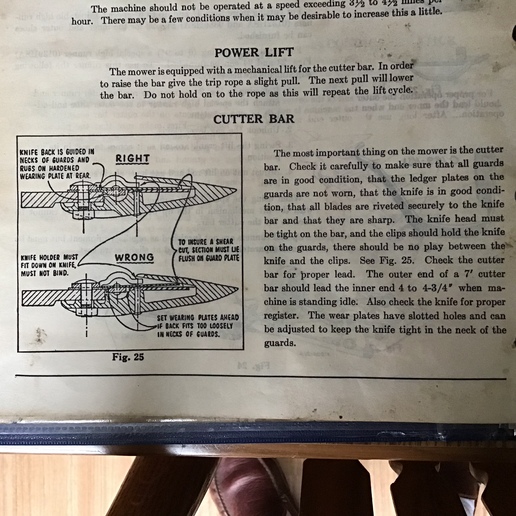

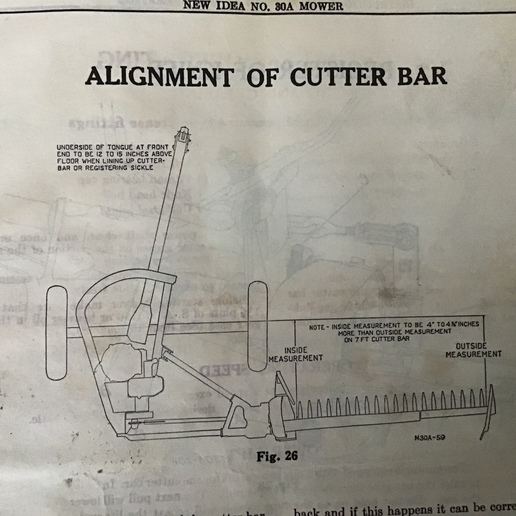

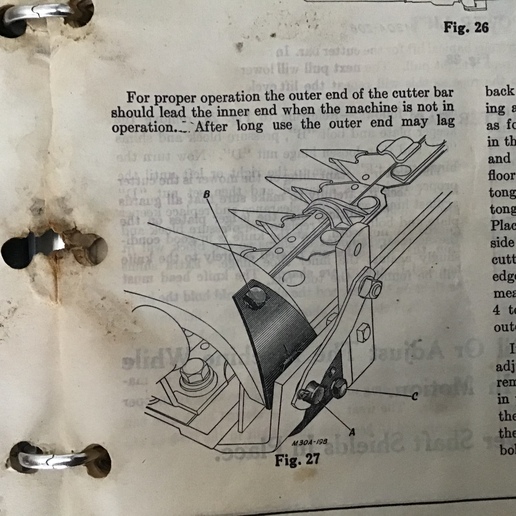

There should not be a gap under the bar right? The hold downs are

not in contact with the bar and now I see I have one that is broke off.

How do I adjust them? I havent had much luck finding a book for

this and Im hoping other manufacturers use a similar design. As

always any help or advice you can give me is greatly appreciated.

Thank you.

ignorance and 30 percent worn or out of adjustment machine. This is

a 1950s? David Bradly sickle mower. Looks like model number 917

5821.

Id love to get this back in working condition but if nothing else I have

to learn how to properly maintain a sickle mower. Heres the issue. I

was using it at the end of summer to mow our pasture. It kept

plugging up. I kept clearing it and trying again. I thought I had it ready

to go. Obviously not! I quit when the clutch was just free spinning. I

was pulling it with a Farmall M in 1st gear open throttle.

Now that I have it in the shop I can turn the PTO by hand and

everything appears to be working. Could I have just gotten the belt

hot and it slipped? The clutch appears to use 4 keys that it engages

on but without disassembly they appear to be intact. Also it appears

the bar is out of adjustment.

There should not be a gap under the bar right? The hold downs are

not in contact with the bar and now I see I have one that is broke off.

How do I adjust them? I havent had much luck finding a book for

this and Im hoping other manufacturers use a similar design. As

always any help or advice you can give me is greatly appreciated.

Thank you.