Crazy Horse

Well-known Member

Just finished up a little job riveting new 3/16 x 1 3/4 x 10 inch woven linings on the 2 brake bands from our club's Massey Harris 101 Junior. The rivets were the hollow end type. I watched a number of videos and pretty much all of them showed relining shoes (2 per side) and not a pair of linings on a single circular band. The videos all showed a guy using a rivet punch with a hammer and an extra set of hands to keep things in place while doing it.

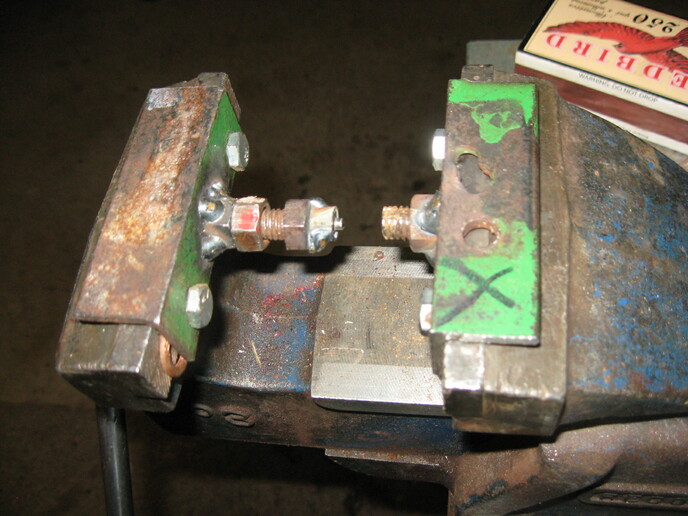

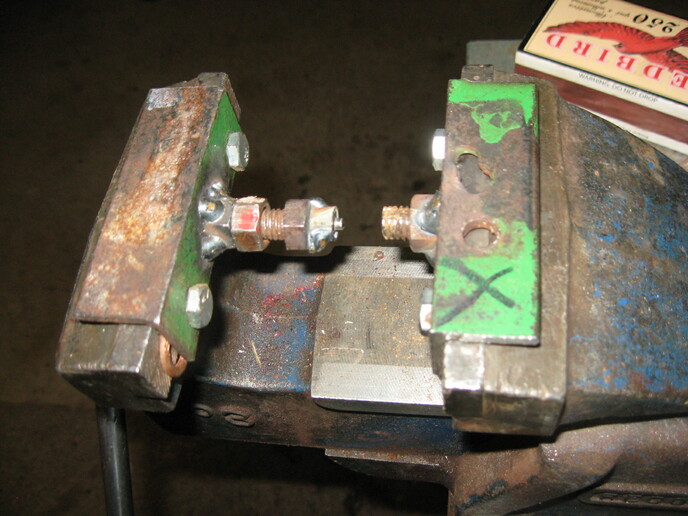

Because the circular band restricted a good hammer blow directly from above, I made up a rivet clincher which bolted up to my bench vise. Photos below explain how it works. In the last photo, you can still see a pair of small bolts and nuts which initially positioned the band in place ..... they were finally removed before the last rivets were squeezed. This part was easy, the trickiest part was making sure your 3/16 inch rivet holes in the lining were in exactly the right place and then countersinking the linings to the correct depth for the rivet heads.

Because the circular band restricted a good hammer blow directly from above, I made up a rivet clincher which bolted up to my bench vise. Photos below explain how it works. In the last photo, you can still see a pair of small bolts and nuts which initially positioned the band in place ..... they were finally removed before the last rivets were squeezed. This part was easy, the trickiest part was making sure your 3/16 inch rivet holes in the lining were in exactly the right place and then countersinking the linings to the correct depth for the rivet heads.