No. For the complete backstory, I have used it with the blower mounted for three seasons. When I bought it, I knew "eyes wide open" that the mid-mount PTO seal had a slow leak. I lived with it that way for a few seasons, but this year the seal failed completely, so it forced my hand and I had to repair it.

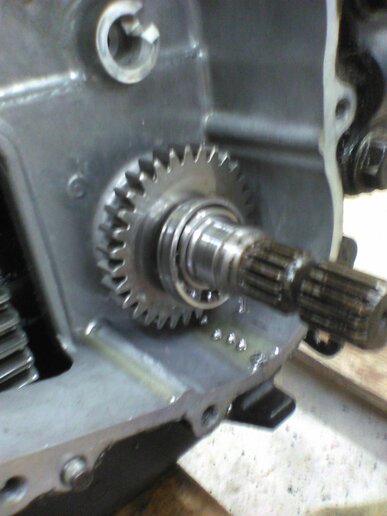

Upon removing the transmission from the tractor and opening the front cover of the transmission, I was able to access the mid-mount PTO output shaft bearings. The outer of the two was completely destroyed:

Fortunately, the front transmission cover (aluminum) was not damaged so I only had to replace the bearing & seal. I put everything back together, and was able to clear the 10 inches of snow that we got with this most recent storm--but with a lot of vibration. In all fairness, this vibration has always been there as long as I owned the tractor. It bothered me, but the tractor worked, and had snow to clear, so I ignored it.

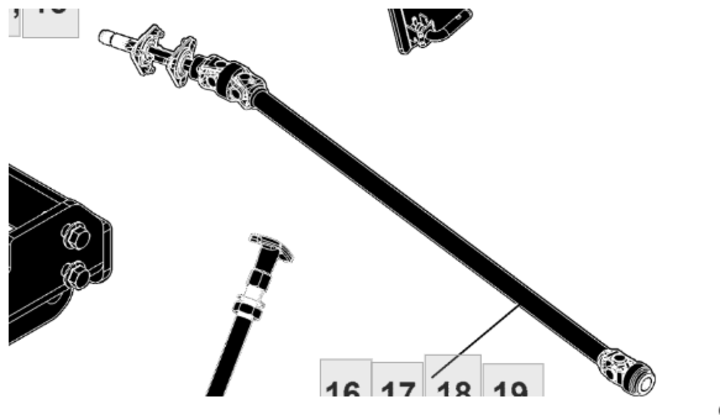

However, not happy that I had just spent several days on my back on a cold concrete floor working on this, I decided to investigate further. This has revealed that the front snowblower bearings have also failed. Now, when I put the snowblower on back in November, the rear-most of the two special-purpose bearings (the two triangles on the front of the PTO shaft) had failed. I had a spare on hand (having just replaced the same one last year!) and put the tractor to work. We get a lot of snow in my area: 10-12 feet is normal. That new bearing failed in 3 months of use. The front has also failed.

So in short, this tractor is eating bearings. The two triangular ones are not too bad to replace aside from the replacement cost and the down-time, but the mid-mount PTO bearing was a lot of work. It is only February. Last year we had our last heavy snow on May 12, 2020! So I have at least 2 more months of winter ahead of me.

If I have to get out, I can run the snowblower and clear the driveway. It will obviously be putting huge strain on the equipment to do so. So I would rather fix it right. In hindsight, I would have fixed it during the summer. You know--that time of the year when we all have lots of "free time" to work on snow-clearing equipment. Ha-ha.

I hate trial-and-error repairs, but I may have to just buy a whole new PTO shaft. I looked at one of the two I have and it is not easily repairable--JD carries it as one complete part. If this were some antique, I would invest the time in a component-by-component rebuild, but I am guessing that is not feasible here even if it were possible.

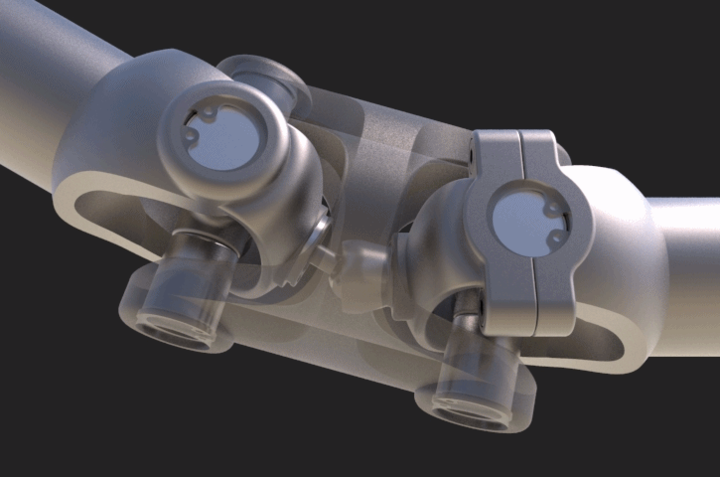

There is nothing obviously wrong with either shaft. They are straight as far as I can tell. The "Cardan joint" seems to work as it should. I greased them thoroughly with the Zerks.

I ran it again with just the PTO shaft in place--no snowblower. The vibration is incredible. Something is clearly wrong. (attempting to post another video, this one without the snowblower.)

<video src="https://www.yesterdaystractors.com/cvvideos/cvvideo78799.mov"

controls>http://forums.yesterdaystractors.com/cvvideos/cvvideo78799.mov</video>