You should upgrade or use an alternative browser.

- Thread starter SVcummins

- Start date

Jim.ME

Well-known Member

- Location

- central ME

Looks like .6985 to me.

Eric in IL

Well-known Member

Roger Tomfohrde

Member

Dennis(IA)

Member

wore out

Well-known Member

(quoted from post at 14:42:09 12/18/20) Looks like 0.647 from here.

Roger has it right.

I didn't catch that the divisions were 0.050", I expected the more common 0.025"

fastfarmall

Well-known Member

Dieseltech

Well-known Member

- Location

- Akron, Indiana

John Deere D

Well-known Member

Jim.ME

Well-known Member

- Location

- central ME

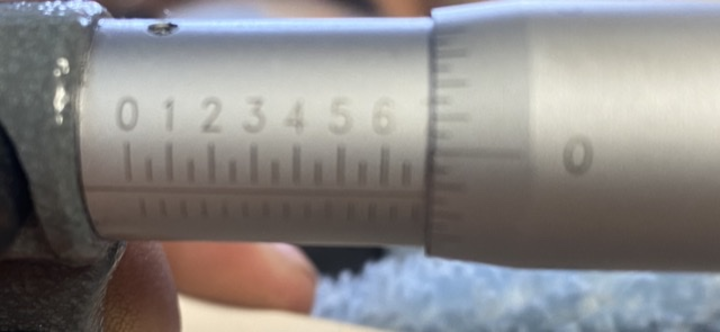

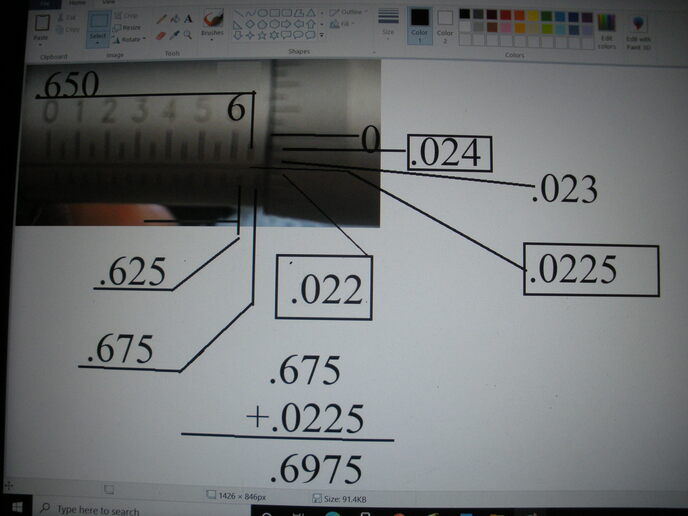

Maybe this will help. It looks like the Thimble is marked in .0005 increments between the .001 increments to me, from what I see in your photo. The .025 increment marks below the line on the sleeve should match 1 full revolution of the thimble for each. So .100" (4 full revolutions of the thimble) between each number on the sleeve.

Jim.ME

Well-known Member

- Location

- central ME

We need a better picture of the thimble to confirm what the divisions are for sure. Show the 0 and the number either side of it, then we can see if it is marked in .0005 increments.

Roger Tomfohrde

Member

DoubleO7

Well-known Member

- Location

- Crystal River, FL

Looks to me past 0.70

And now 0.70125

Jim.ME

Well-known Member

- Location

- central ME

Thimble has right hand thread. It would be on the other side of the 0 (backed out more) if it was over .700".

Eric in IL

Well-known Member

Dennis(IA)

Member

Sooo the thimble is reading .6975”

DoubleO7

Well-known Member

- Location

- Crystal River, FL

(quoted from post at 20:11:02 12/18/20)

Thimble has right hand thread. It would be on the other side of the 0 (backed out more) if it was over .700".

Oops my bad

Dennis(IA)

Member

Jim.ME

Well-known Member

- Location

- central ME

To answer that we need to see more of the numbers on the thimble to see what the numbers are and how many marks between them. Or SV needs to tell us how many turns it takes to go from one number on the sleeve to the next.

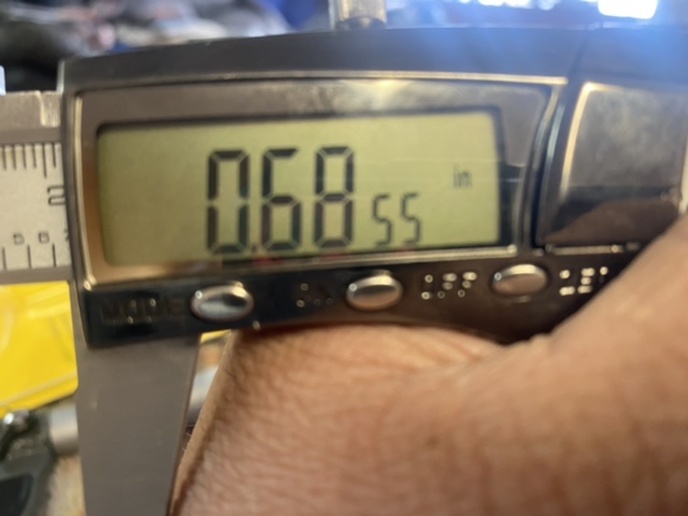

The .012 (+/-) bust between the mic and caliper would be a concern to me and could be a number of things. Not knowing what he is measuring, it may not matter in the end.

Jim.ME

Well-known Member

- Location

- central ME

(quoted from post at 23:39:59 12/18/20) I am even more confused than when I starred 😐.

<img src="https://www.yesterdaystractors.com/cvphotos/cvphoto67614.jpg">

How many complete turns of the thimble does it take to move from the #5 line on the barrel (aka sleeve) to the #6 line? How many lines, total, are there around the thimble?

Jim.ME

Well-known Member

- Location

- central ME

(quoted from post at 00:09:38 12/19/20) The thimble is .25 thousandths per revolution or one little

mark on the barrel

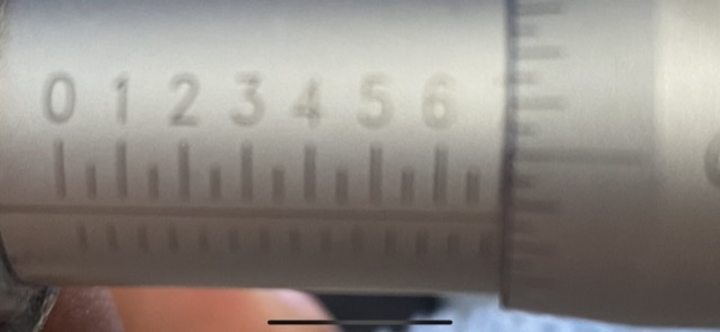

Thanks, the thimble moves 25 thousandths per revolution. What is the total number of marks, long and short, around the thimble? 25 or 50. From counting visible marks on the thimble in your pictures, it looks like it may be 50, in which case the thimble is graduated for one-half thousandths.

Jim.ME

Well-known Member

- Location

- central ME

(quoted from post at 16:07:43 12/19/20) Each little mark on the thimble is - 500 a hundredth or half a thousandth

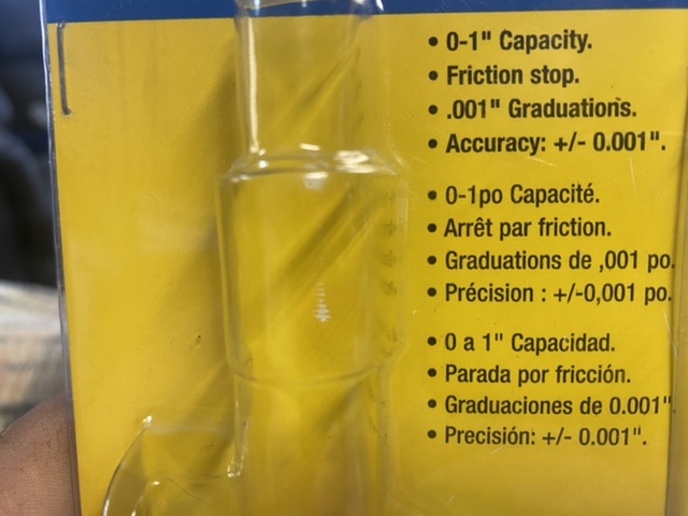

Thank you for clearing this up, the small marks are each 1/2 thousandth as I thought. The packaging may say graduated in .001" but the thimble of the one you have is graduated on .0005" increments. So your reading that started this was about .6985", .0015 less than .700. The angle of your picture may be throwing that reading off a bit as compared to looking at it square on, in hand.

As for the .010" difference between the caliper and mic, it could be several things; calibrations may be off, piece you were measuring might be out of round, operator "feel" was likely different, changing temperature, for somethings. Even the temperature from your hand can make a difference. The calibration shop I take things to won't do a calibration until the tool sets in their lab for 24 hours so it is the same temp as the calibration gear.

I'd very much doubt that a cheap mike was graduated in 1/2 thou's, which would mean the barrel was threaded at 80TPI?

Jim.ME

Well-known Member

- Location

- central ME

The edit feature does not work presently, due to issues between classic and modern views I believe, and has been discussed many times.

I already asked that question and SV has answered it. One turn moves 25 thousandths. The last picture of a General #102 mic is one I posted it to show the difference in the thimble graduations. That is one I consider graduated in thousandths on the thimble, with 25 marks around the circumference.

From the picture of the packaging I am guessing it is a General, that is not confirmed. General provides some good tools, at a reasonable price, which meet the needs of many. I have some of their tools, so I am not bashing them.

Some research of images reveals General had some, like SV's, with 50 marks around the thimble (with travel 25 thousandths per revolution). I call that graduated in .0005", even though packaging says graduations are .001" (Its not graduated in millimeters). Research also found General also had some carbide faced mics at one time. They may not have actually produced all the mics they sold. They may have had some branded from other sources, which could axplain the differences over the years. Many brands of "cheap" mics have .0005" graduations and carbide faces, so price doesn't always control what you get. Many are surprisingly accurate, at least in the beginning. How accurate they, or any mic, remain over the years can only be checked by regular calibration. I have seen "cheap" mics pass calibration and "expensive" ones fail.

Jim.ME

Well-known Member

- Location

- central ME

Here is a General with .0005" marks, like SV's.

Similar threads

- Replies

- 4

- Views

- 865

We sell tractor parts! We have the parts you need to repair your tractor - the right parts. Our low prices and years of research make us your best choice when you need parts. Shop Online Today.

Copyright © 1997-2024 Yesterday's Tractor Co.

All Rights Reserved. Reproduction of any part of this website, including design and content, without written permission is strictly prohibited. Trade Marks and Trade Names contained and used in this Website are those of others, and are used in this Website in a descriptive sense to refer to the products of others. Use of this Web site constitutes acceptance of our User Agreement and Privacy Policy TRADEMARK DISCLAIMER: Tradenames and Trademarks referred to within Yesterday's Tractor Co. products and within the Yesterday's Tractor Co. websites are the property of their respective trademark holders. None of these trademark holders are affiliated with Yesterday's Tractor Co., our products, or our website nor are we sponsored by them. John Deere and its logos are the registered trademarks of the John Deere Corporation. Agco, Agco Allis, White, Massey Ferguson and their logos are the registered trademarks of AGCO Corporation. Case, Case-IH, Farmall, International Harvester, New Holland and their logos are registered trademarks of CNH Global N.V.

Yesterday's Tractors - Antique Tractor Headquarters

Website Accessibility Policy