There was a topic around here where SV mentioned using break in oil. I was at the caseih dealer Thursday and asked about it. No they didn't have it but he said they usually use Rotella cause it is high in zinc. This prompted some research.

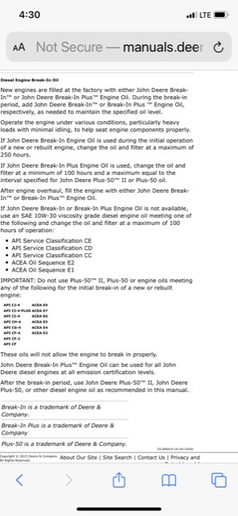

Break in oil is basically non-detergent mineral oil that doesn't have all the friction reducers that regular oil and synthetic oil has. The regular friction from the plain mineral oil is what causes the rings and cylinder wall to wear in much quicker and seat the edges of the rings after a few hours.

However with a new engine with a new cam you don't want the cam lobes to wear like you want the rings and cylinders. So they add a bunch of zinc and phosphorus to break in oil to keep the cam lobes from getting wore down during the break in period.

So when I get my C221 bored to C301 engine back from the shop with its original cam, I plan to use the 30 weight HD 30 weight non detergent oil that can be bot which is what we used to run in mowers all the time.

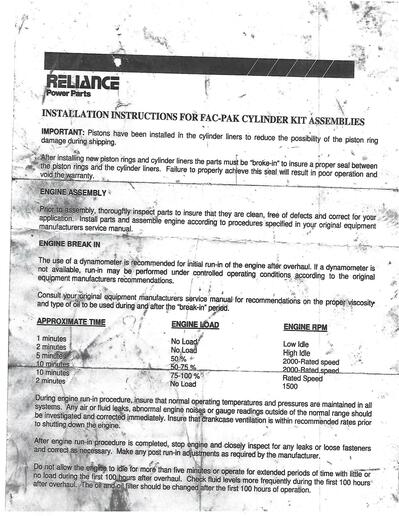

Then run it for a number of hours or a day at varying rpms and loads to break it in. Then drain and replace with a 15w40 of choice brand.

That is my plan now anyways. But I wanted to open this up for discussion and see what you experts have to say. Thanks.

Break in oil is basically non-detergent mineral oil that doesn't have all the friction reducers that regular oil and synthetic oil has. The regular friction from the plain mineral oil is what causes the rings and cylinder wall to wear in much quicker and seat the edges of the rings after a few hours.

However with a new engine with a new cam you don't want the cam lobes to wear like you want the rings and cylinders. So they add a bunch of zinc and phosphorus to break in oil to keep the cam lobes from getting wore down during the break in period.

So when I get my C221 bored to C301 engine back from the shop with its original cam, I plan to use the 30 weight HD 30 weight non detergent oil that can be bot which is what we used to run in mowers all the time.

Then run it for a number of hours or a day at varying rpms and loads to break it in. Then drain and replace with a 15w40 of choice brand.

That is my plan now anyways. But I wanted to open this up for discussion and see what you experts have to say. Thanks.