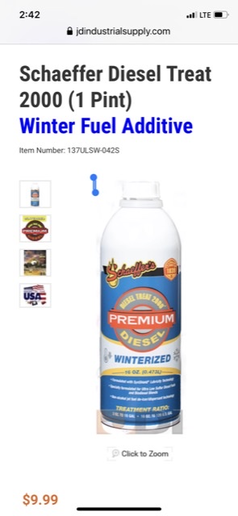

This is my first winter with my John Deere R, and F350 with the 6.9 idi. What do I need to know about diesels in the winter? I buy road diesel at a Marathon station, and off-road diesel at the local farm fuel station. Do I need additives? I don’t plan on using the truck or tractor when it’s below 20*F, but things come up, so I might need to use them when it’s below 20*F.

Also I have 6 5gallon cans of off-road diesel that I bought in August, do I need to do something special with that before I can use it.

Any advice is appreciated.

Also I have 6 5gallon cans of off-road diesel that I bought in August, do I need to do something special with that before I can use it.

Any advice is appreciated.