smokejmp52

New User

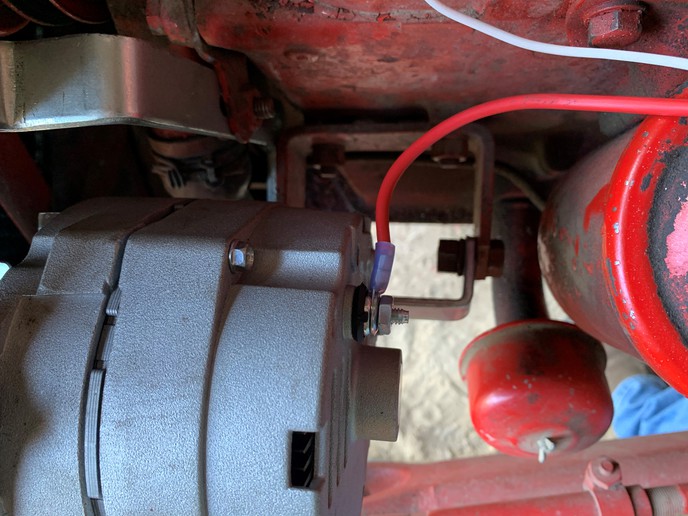

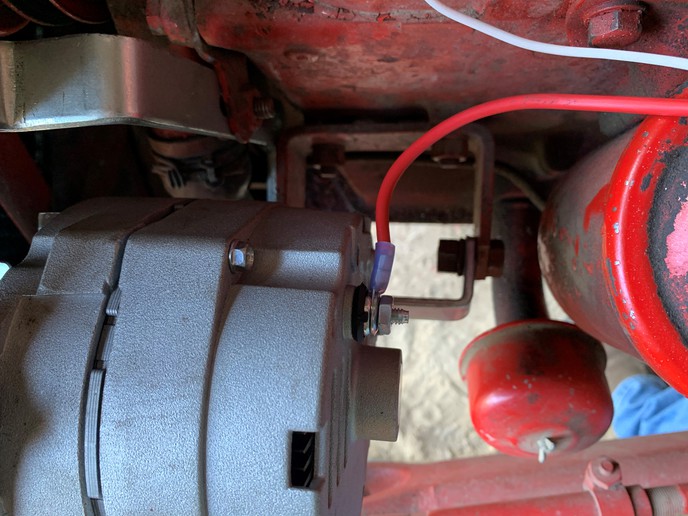

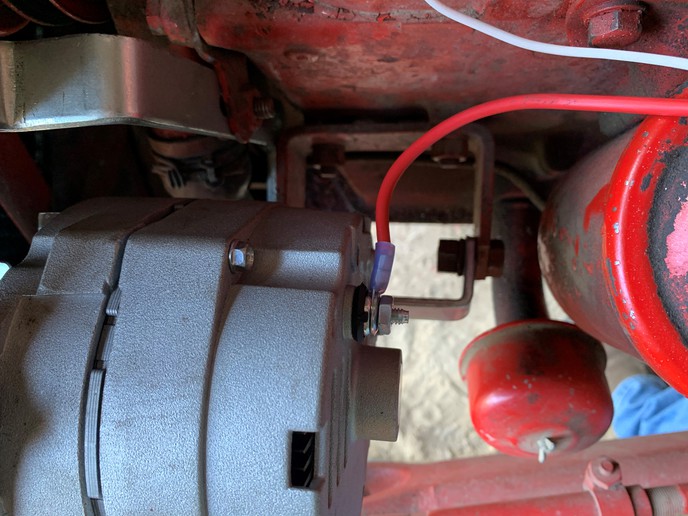

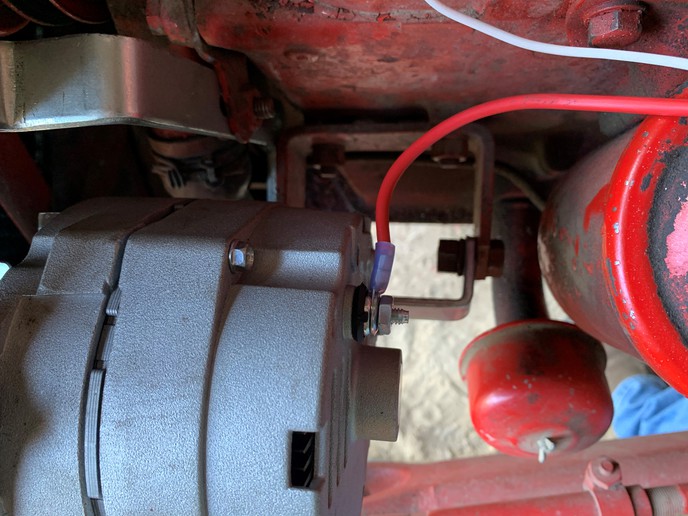

I purchased this kit and had a heck of a time mounting it because the directions were terrible and the bolts won't fit through the slide channels where they say it should. Does this look right to anyone. The top bracket is opposite mounted of what directions show and the bracket that uses the mount from the old generator makes the nut barely fit the bolt after leaving the lock washer off. This kit came from this site. Any thoughts?

his kit came from tbis

his kit came from tbis