grandpa Love

Well-known Member

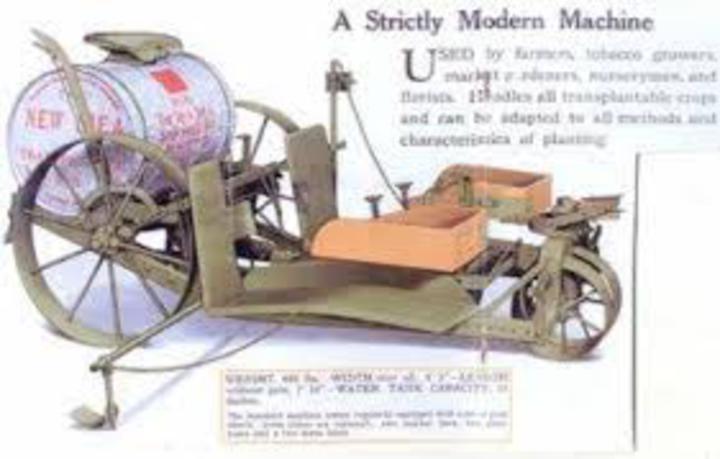

We saw this at Tracy Brown's last month and I couldn't wait to get back up there to get it. Yesterday was a great day for a road trip, with Grandma's shoulder issue. Took a slow trip up to north Mississippi. Old planter seems to all work. Can't wait for the next tractor show, bet no one else has one! Been looking around the internet and haven't found one like it. Any of y'all ever seen or used one? Patent was issued in 1940, I believe it used to be horse drawn.

I may end up with an acre of sweet potatoes!!

I may end up with an acre of sweet potatoes!!