Rich'sToys

Well-known Member

- Location

- Southern MN

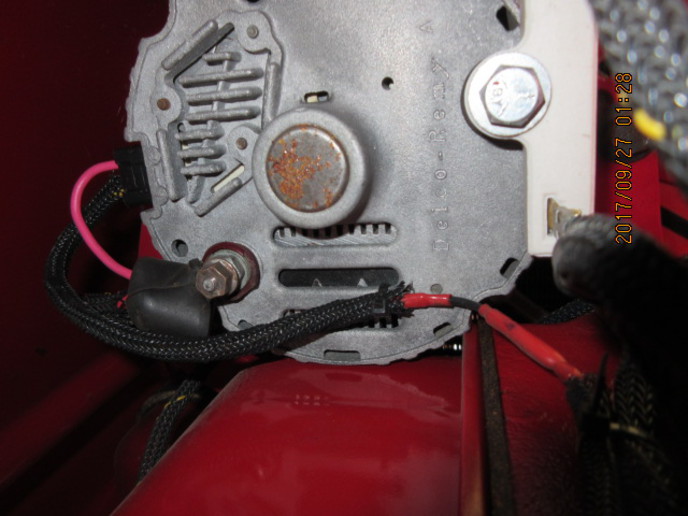

Has anyone used these? Some friends are working on a Farmall M which has been switched over to 12 volts. In order for the alternator to fit under the hood they need a shorter belt than they have. They have only been able to locate belts in 1" increments, and the next 1" smaller is too short.

I'm not that familiar with these link belts, but was wondering if one of those might work in this application.

Has anyone had any experience with these? Do they come in 1/2" increments? Are they rated for this type of use? When I googled it I read where many of them are used on such things as table saws, etc.

Any thoughts would be appreciated.

I'm not that familiar with these link belts, but was wondering if one of those might work in this application.

Has anyone had any experience with these? Do they come in 1/2" increments? Are they rated for this type of use? When I googled it I read where many of them are used on such things as table saws, etc.

Any thoughts would be appreciated.