Has anybody fixed a cracked engine block with any

success ? I?ve seen them repaired before had one

in a Massey Ferguson combine that we had welded

and it worked good for as long as we had the

machine sold it with the cracked block and I don?t

know what ever happened to it after that . Anyway

trying to decide if I should try welding it or use a

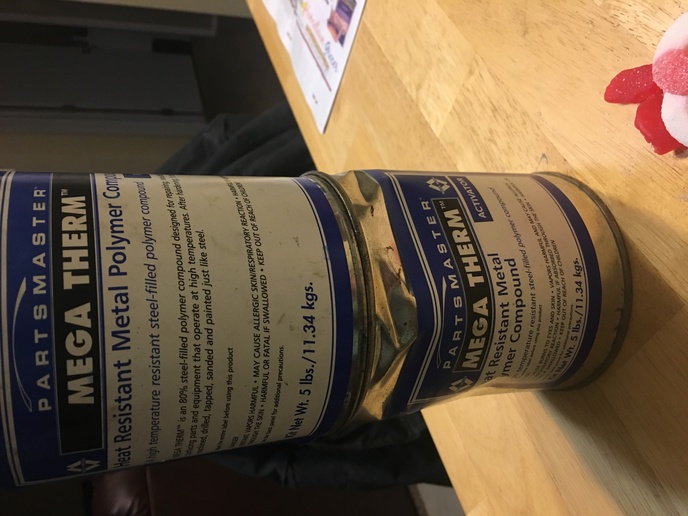

cold weld epoxy has anybody ever used parts

master mega therm I guess it cost 800$ for the two

parts

success ? I?ve seen them repaired before had one

in a Massey Ferguson combine that we had welded

and it worked good for as long as we had the

machine sold it with the cracked block and I don?t

know what ever happened to it after that . Anyway

trying to decide if I should try welding it or use a

cold weld epoxy has anybody ever used parts

master mega therm I guess it cost 800$ for the two

parts