Adirondack case guy

Well-known Member

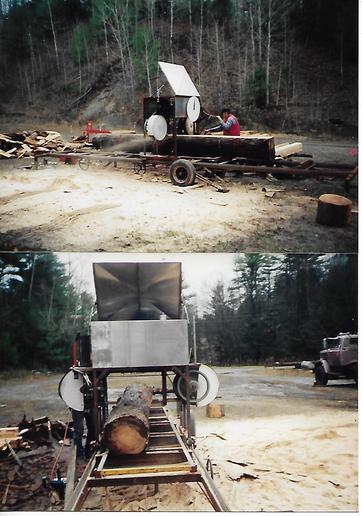

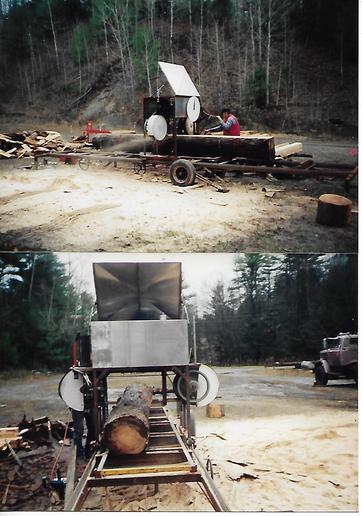

I built this back in late 80s. Sawed a few K feet of lumber with it. It can saw a 30" log 24' long. Pics were in 1990 I think, taken before it got painted.

I powered it with a 14hp Kohler engine off a Case 444 GT. I bought the band drive wheels, bands, and guide wheels from Timber-Tech. The transport axle came from an old trailer home. All the rest I fabricated from new steel and scraps. The trolley wheels came from an industrial bearing supply and are V shaped and run on inverted angle iron welded to the bed rails. The trolley has lockdowns for road transport. When I set the mill up to saw, I have the front end about 2 inches higher than the rear and the trolley pretty well self feeds. There is a safety brake to lock the trolley to hold it at the front of the bed, when canting the logs on the bed.

I haven't run it for about 15 years now. I stole the engine back off it, and need to replace that, and get it running again. I still have a couple of new bands for it.

Loren

I powered it with a 14hp Kohler engine off a Case 444 GT. I bought the band drive wheels, bands, and guide wheels from Timber-Tech. The transport axle came from an old trailer home. All the rest I fabricated from new steel and scraps. The trolley wheels came from an industrial bearing supply and are V shaped and run on inverted angle iron welded to the bed rails. The trolley has lockdowns for road transport. When I set the mill up to saw, I have the front end about 2 inches higher than the rear and the trolley pretty well self feeds. There is a safety brake to lock the trolley to hold it at the front of the bed, when canting the logs on the bed.

I haven't run it for about 15 years now. I stole the engine back off it, and need to replace that, and get it running again. I still have a couple of new bands for it.

Loren