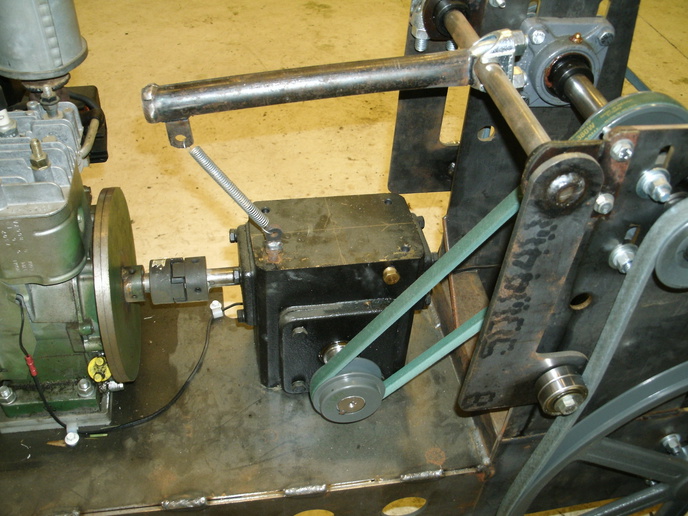

Didn't know which Forum to post this, but I built me a 1/3 scale baler this spring and then finally got the chance to test it out yesterday and do some minor adjustments on it. Seems to work well, except that I'm getting more hay in the bottom of the bale than at the top and they banana a little. I don't know how to overcome gravity! I shortened my plunger twice yesterday as I thought it was pushing the grass too far down into the chamber. It helped it some, but it's still doing it. I tried putting hay in it sideways, lengthways, loose (every which direction) and it doesn't seem to help much. I know on a regular baler, you can adjust the feeder forks to position the hay in the chamber so it's more centered, but when you're doing it manually with a hay press like this, you don't have that adjustment. Any ideas on what I'm doing wrong? Also-just to clarify, I am testing this out by just feeding it from the top and not using the bale pick up and auger yet. They work, but for now I'm just testing it out as a stationary press until I get the bugs worked out and then I'm going to paint it. Thanks,

Pat in Montana

Pat in Montana