super99

Well-known Member

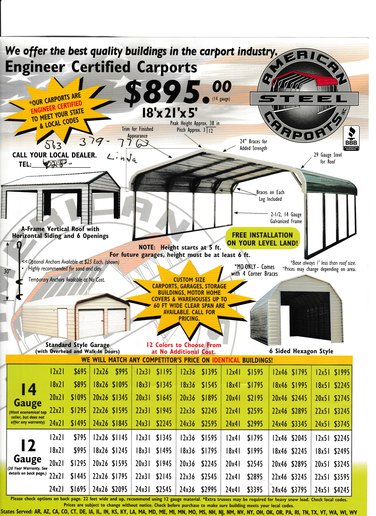

The wind is tearing up my carport that I bought in Dec. of 2012. Today I had to go out and tighten most of the screws on the braces and uprights. There were 5 missing screws out of the lower edge of the roof sheeting. They are a #12x3/4" self tapping screw. Some will not hold anymore and I have had to replace them with larger screws. I have to do this about 4 times a year. I had longer end braces made and replaced the short ones on the corners with the longer ones and it seemed to help, but they still work loose. Is there a better fastener to use than the self tapers? Am I going to have to buy whatever it is I need to be able to weld aluminum with my mig welder and weld all the joints? Does anyone else have this problem or is it just me?? Chris