Farmall706guy

Member

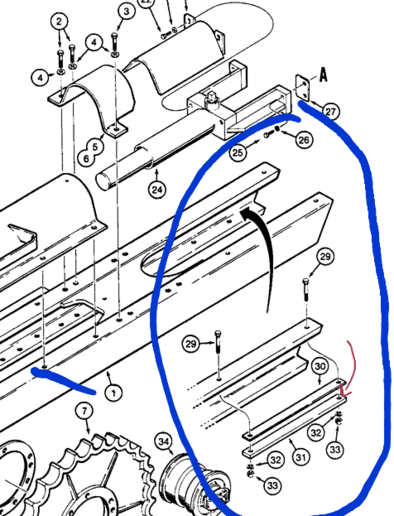

Hi RBoots, lets get right into this. so you said that the bolt right in front of the idler pulley held the wear strip on, Well i kind of won this war and lost this war at the same time, see, i removed the bolt, on both sides and successfully tightend up both tracks perfectly today before i logged on and found that you said that the bolts hold on the wear strip and i never new until i just seen you reply, so i took them bolt out and tighten up my track and i was so happy, you know, obviously!, and then i drove it like 150 feet to get it out of the way of the workshop. I hope i didn't hurt anything with that bolt missing holding the wear bar on. So basically your saying that i cannot run the dozer with that bolt missing then. unless i welded something, do you think you could show me a picture of what would need to be welded? sorry for asking to much, i just, i hope i can easily weld this wear bar, because after the bolts, and everything, i really got my tracks snug like they are supposed to be, its great.. Thank you Ross.

Levi

Levi