Geo-TH,In

Well-known Member

The past 50 hrs my 2012 Kawasaki mule 4010 has had only idling issues. Nail the gas and runs as

it should. I even bought a service manual from dealer. Same manual the service techs use. You

name it, I've done it. EVERYTHING is within factory specs. No codes on computer. It has clean air

filter, new plugs, cleaned fuel filter, fuel flow and fuel pressure is at specs. The throttle

body has two throttle plates, one is manual the other is computer controlled. Both have a tps. I

even replaced the manual tps. Bought a camera to look inside throttle plate, cleaned it with sea

foam. There are two temp sensors, one is air the other is engine temp. Both sensors have the same

resistance with the same temp. Resistance changes as they should with temp.

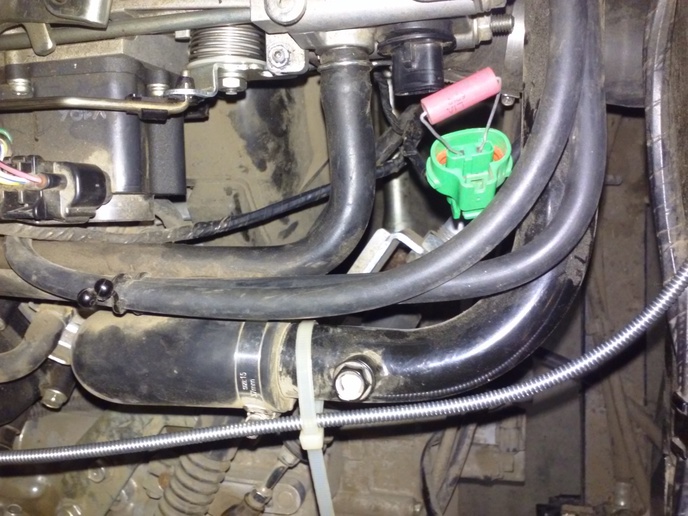

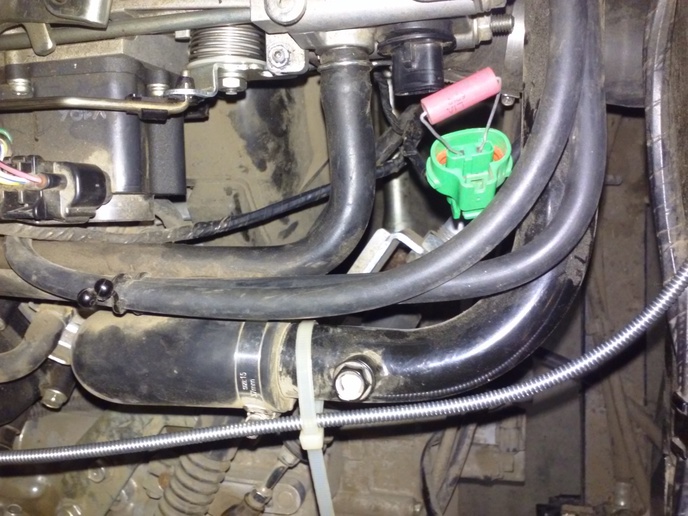

So this morning I decided to play a trick on computer. I replaced air temp sensor with a 1600 ohm

fixed precision resistor. After I took the pic, I covered the resistor with electrical tape so it

wouldn't short out. The computer now thinks it's 98 degrees when the actual air temp is 62. At 62

degrees the air temp and water temp resistance readings were the same this morning, 2300 ohms,

well within factor specs.

Today, it idled as it did when new. Be interesting to see what happens when the air temp changes.

If needed, I may install a fixed resistor in series with variable resistor to have the ability to

safely dial in a range of resistance values of the thermal resistor. Hope this works. I'm about

to give up. Been thinking I made a mistake buying a UTV with fuel injection. Carburetors are not

that hard to work on.

Who has tricked a computer using resistors?

it should. I even bought a service manual from dealer. Same manual the service techs use. You

name it, I've done it. EVERYTHING is within factory specs. No codes on computer. It has clean air

filter, new plugs, cleaned fuel filter, fuel flow and fuel pressure is at specs. The throttle

body has two throttle plates, one is manual the other is computer controlled. Both have a tps. I

even replaced the manual tps. Bought a camera to look inside throttle plate, cleaned it with sea

foam. There are two temp sensors, one is air the other is engine temp. Both sensors have the same

resistance with the same temp. Resistance changes as they should with temp.

So this morning I decided to play a trick on computer. I replaced air temp sensor with a 1600 ohm

fixed precision resistor. After I took the pic, I covered the resistor with electrical tape so it

wouldn't short out. The computer now thinks it's 98 degrees when the actual air temp is 62. At 62

degrees the air temp and water temp resistance readings were the same this morning, 2300 ohms,

well within factor specs.

Today, it idled as it did when new. Be interesting to see what happens when the air temp changes.

If needed, I may install a fixed resistor in series with variable resistor to have the ability to

safely dial in a range of resistance values of the thermal resistor. Hope this works. I'm about

to give up. Been thinking I made a mistake buying a UTV with fuel injection. Carburetors are not

that hard to work on.

Who has tricked a computer using resistors?