Just in case the post I put in the restoration

thread gets lost in space.

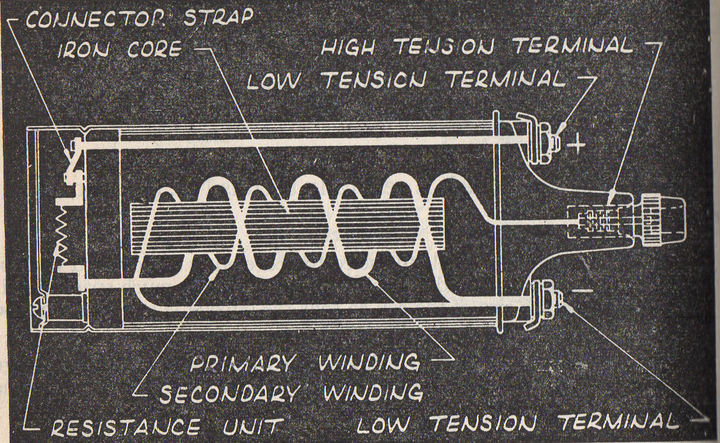

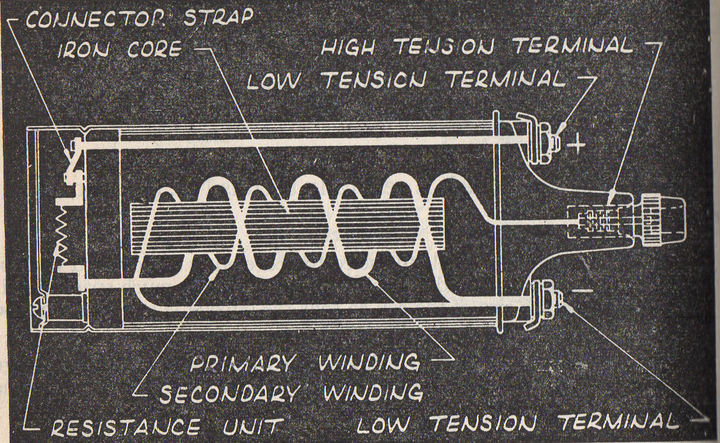

Back in the "old days' of autos, many companies

used ignition coils with built in ballast

resistors and sometimes built in capacitors.

Delco, Atwater-Kent, and Remy certainly had

them. In the 1930s - Delco listed four

different type coils.

#1 ROUND TYPE WITH STRAW-COLORED SHELL - has no

condensor or resistor built in.

#2 ROUND TYPE WITH BLACK SHELL - built in

resistance unit but no condensor

#3 D-TYPE WITH BAKELITE SHELL - resistance unit

built into top of coil can.

#4 d-TYPE WITH BLACK SHELL - condensor and

resistance until built into end of coil can.

thread gets lost in space.

Back in the "old days' of autos, many companies

used ignition coils with built in ballast

resistors and sometimes built in capacitors.

Delco, Atwater-Kent, and Remy certainly had

them. In the 1930s - Delco listed four

different type coils.

#1 ROUND TYPE WITH STRAW-COLORED SHELL - has no

condensor or resistor built in.

#2 ROUND TYPE WITH BLACK SHELL - built in

resistance unit but no condensor

#3 D-TYPE WITH BAKELITE SHELL - resistance unit

built into top of coil can.

#4 d-TYPE WITH BLACK SHELL - condensor and

resistance until built into end of coil can.