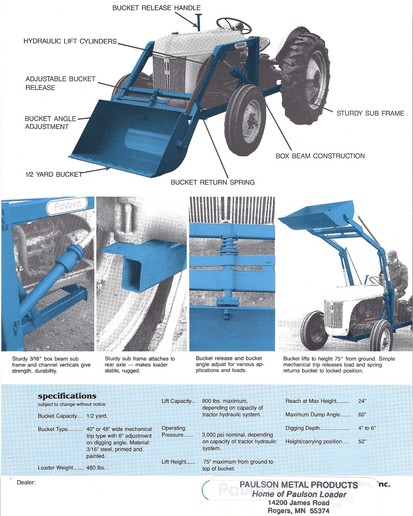

Need to replace the fender retaining bolts on my ford jubilee to secure the rear mounts for the Paulson loader I bought.Anybody know how the size and length of these bolts? I think they are carriage bolts

Need to know the size , thread, and app. lengths h of the bolt that secures the front crankshaft pulley to the crankshaft .Have to remove nut that with the hand crank and replace it with a bolt that

will clear the flex coupling for the pump drive shaft.Learned from Old that the nut is standard right hand thread. I would like to know size, app. length and if it is fine or coarse thread

My tractor is 100 miles from our place in Seattle Wa

Need to know the size , thread, and app. lengths h of the bolt that secures the front crankshaft pulley to the crankshaft .Have to remove nut that with the hand crank and replace it with a bolt that

will clear the flex coupling for the pump drive shaft.Learned from Old that the nut is standard right hand thread. I would like to know size, app. length and if it is fine or coarse thread

My tractor is 100 miles from our place in Seattle Wa