Zachary Hoyt

Well-known Member

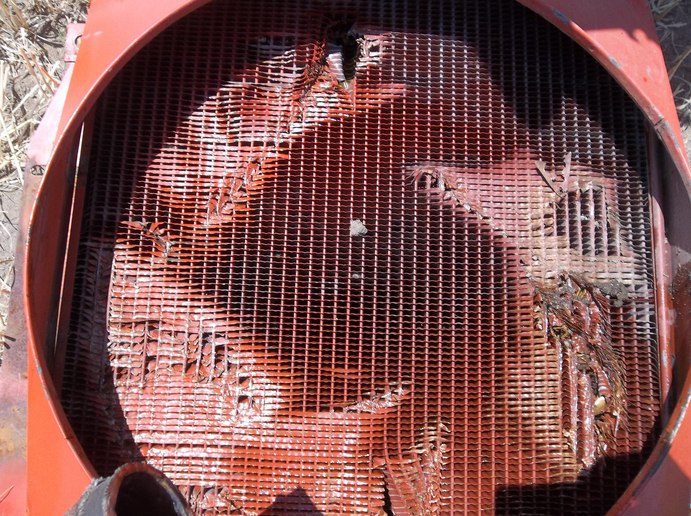

I thought I had seen it all but now I am completely stumped.

Was out mowing hay with the Massey 35 which is my backup

tractor since the Farmall had a problem this morning. 35 has

been overheating, gradually worse over the years. I just try to

clean the radiator fins and carry on, and when the temp gauge

gets hot I wait till it cools down. Tonight I heard a sound and

when I shut off the tractor to look I saw that two of the fan

blades had broken off right by where they are riveted to the hub

on the water pump. They are opposite blades on a 4 blade fan,

what would be 3 and 9 oclock. The other two are still there and

look fine, there is no sign of damage to the tips like they had hit

anything. I was able to find one of the broken off blades and it

looks like it was metal fatigued or something. One blade made a

hole in the radiator near the top. I have never seen this happen

before, if anyone can shed any light on the problem I would

appreciate it.

Zach

Was out mowing hay with the Massey 35 which is my backup

tractor since the Farmall had a problem this morning. 35 has

been overheating, gradually worse over the years. I just try to

clean the radiator fins and carry on, and when the temp gauge

gets hot I wait till it cools down. Tonight I heard a sound and

when I shut off the tractor to look I saw that two of the fan

blades had broken off right by where they are riveted to the hub

on the water pump. They are opposite blades on a 4 blade fan,

what would be 3 and 9 oclock. The other two are still there and

look fine, there is no sign of damage to the tips like they had hit

anything. I was able to find one of the broken off blades and it

looks like it was metal fatigued or something. One blade made a

hole in the radiator near the top. I have never seen this happen

before, if anyone can shed any light on the problem I would

appreciate it.

Zach