Anonymous-0

Well-known Member

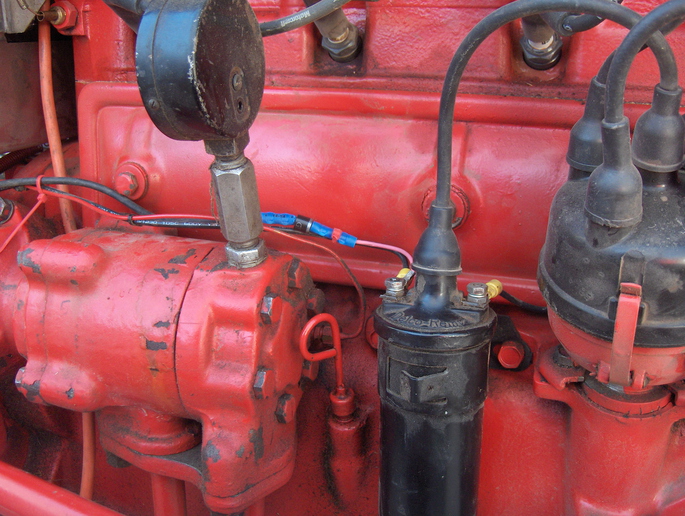

One of my tractors was very difficult to start in cooler to cold weather. It would crank fine but no fire. If I jumper from a running vehicle, it would fire right up.

I finally got around to study the situation. When I turned the ignition ON (not running), I measured a little less that 5 volts at the coil. I measured the ignition resistor and measured 2 Ohms. I went to the local farm store for a replacement it was also 2 Ohms. I measured the DC resistance of the coil and came up with 1.8 Ohms. I installed a 1.8 Ohm resistor and now all is well.

The moral of the story, make sure the ignition resistor matches your coil.

I finally got around to study the situation. When I turned the ignition ON (not running), I measured a little less that 5 volts at the coil. I measured the ignition resistor and measured 2 Ohms. I went to the local farm store for a replacement it was also 2 Ohms. I measured the DC resistance of the coil and came up with 1.8 Ohms. I installed a 1.8 Ohm resistor and now all is well.

The moral of the story, make sure the ignition resistor matches your coil.