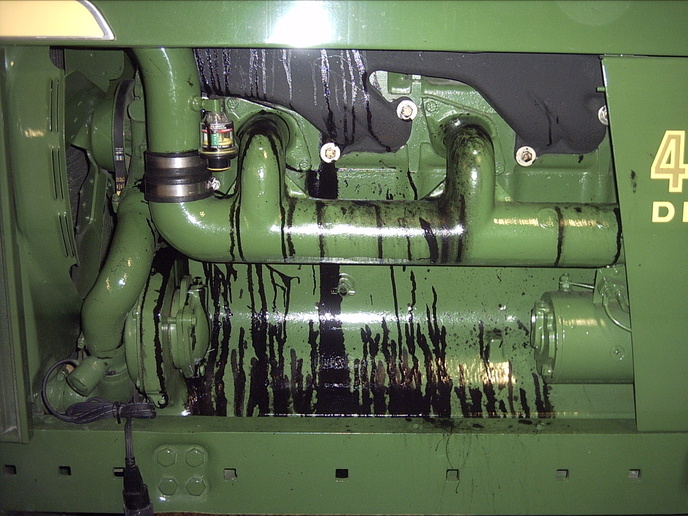

I need some expert advice...I ahve a '68 4020 diesel. My problem is that it is slobbering excessively out the stack and down the side of the manifold and down the engine block. It has 25 hours on a new inj. pump and injectors. I also reset the valve tappets at that time.

Here's what I have done to trouble-shoot: checked and fine-tuned the timing a bit.(it runs and sounds great with almost no blowby and the exhaust is clear with a slightly black tint), I cracked the injectors to see if there is a miss...every cylinder firing. The temp gauge needle comes up after about 10-15 minutes in cold weather. Sometimes it comes up about half-way(to the "N" mark), on colder days, only comes up about 1/4 of the way.

The last thing I did was remove the manifold for planing because I thought the front port was leaking. When I got it off, I could see that #1 chamber was wet. Maybe a bad valve/valve guide/valve seal? It runs so good that I can't imagine it being a bad cylinder. What do you think?

Thanks!

Heath

Here's what I have done to trouble-shoot: checked and fine-tuned the timing a bit.(it runs and sounds great with almost no blowby and the exhaust is clear with a slightly black tint), I cracked the injectors to see if there is a miss...every cylinder firing. The temp gauge needle comes up after about 10-15 minutes in cold weather. Sometimes it comes up about half-way(to the "N" mark), on colder days, only comes up about 1/4 of the way.

The last thing I did was remove the manifold for planing because I thought the front port was leaking. When I got it off, I could see that #1 chamber was wet. Maybe a bad valve/valve guide/valve seal? It runs so good that I can't imagine it being a bad cylinder. What do you think?

Thanks!

Heath