Hobo,NC

Well-known Member

- Location

- Sanford, NC

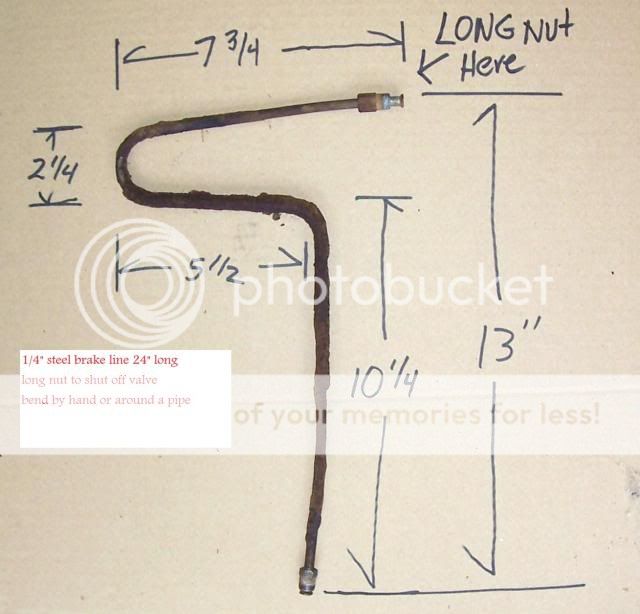

Been fudgen with this beast 'bout all winter,,, man verses BEAST,,, went thru new a replacement it leaked,,, found the tank leaked were the shut off valve mounts to the tank,,, never could solder it so did the por 15 thang,,, I had a original nice shut off BUT the shut off was so loose the vibration would back it out and restrict fuel flow,,, never could figger out what to do to help that SOOOOOO I backed the screw out and put some blue loctite on it, ran it in and backed it out a turn and a haft,,, its locked in place so the best I could come with was this shut off at the carb,,,, mite would of tried to git it in the original line but it it did not go well I did not wanna pull the tank off to replace the fuel line,,, I have a NAPA # A6765 shut off, one 8" 1/4" fuel line and a 12" 1/4" line and union,,, hope I am done with it,,, would not have messed with the different steel lines but I could not find the line nuts local so had to chop up some for the nuts

[/img]

[/img]