1946 BN IHC

Member

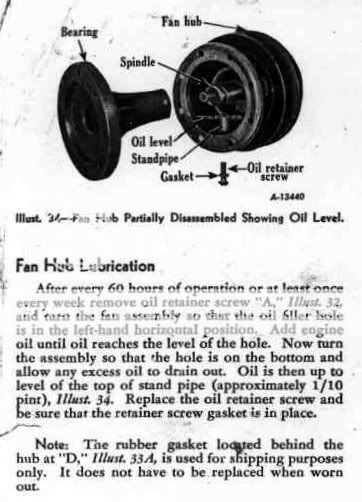

I have the oil bath fan pully apart to check out and repaint. In side I find that all is in excellent shape for a tractor of 60 years plus. What confuses me is the obvious lack of a seal at the sahft end. To my way of thinking and mechanics a seal is needed to keep out contaminates and oil in along the shaft. I have searched for a felt seal with no success as of yet with out it the above would obviously take place.I cant see IHC making a pully on a shaft with out installing a seal in the housing to seperate the exterior from the interior.

Suggestions comments and dirctioin to locate such a seal piece.

Thank you .

Wm.

Suggestions comments and dirctioin to locate such a seal piece.

Thank you .

Wm.