[b:45994a82b2]Hey all, Been wanting to get a loader for my 300 narrow front so I was searching craigslist the other day and found an IH 2001 loader with trip bucket for $325 about an hour from my house. Contacted the seller, the guy bought the loader for a Farmall H but then sold the H and is now selling the loader. Told him I'd like to check it out this weekend weather permitting. Whats your opinions on it? Ill post the ad...

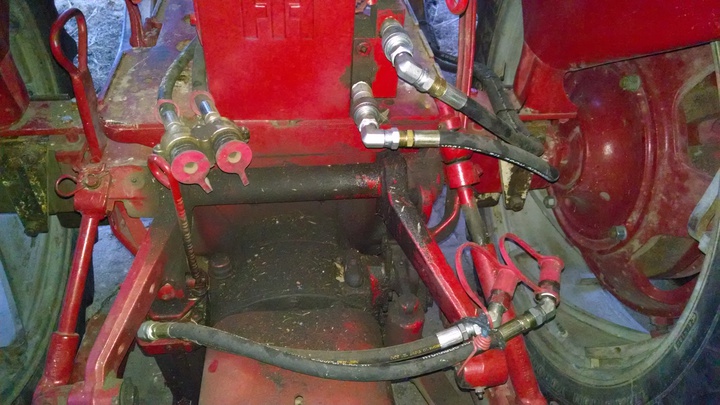

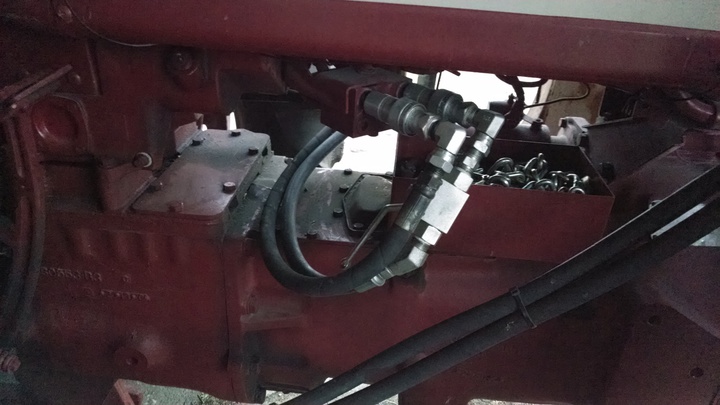

Other than the obvious checking for cracks/repairs in the frames is there anything else I should look at? I will more than likely (have to) replace the hoses. If the cylinders leak are there any kits I can get to fix them?

heres the Ad:[/b:45994a82b2]

http://harrisburg.craigslist.org/grd/4327030726.html

Other than the obvious checking for cracks/repairs in the frames is there anything else I should look at? I will more than likely (have to) replace the hoses. If the cylinders leak are there any kits I can get to fix them?

heres the Ad:[/b:45994a82b2]

http://harrisburg.craigslist.org/grd/4327030726.html