Hi got a 55 IH 300 utility. Just bought it 3 weeks ago so its new to me. Wow only 1700 hrs on it for a 58 year old.

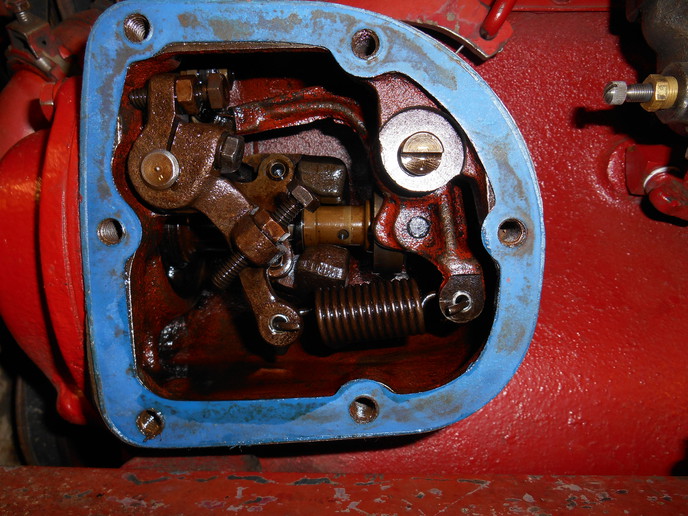

Anyways... I am at wits end with it. I can"t get any more revs out of it than 1500. I have rebuilt the carb new gas filter new plugs cleaned the gas tank and sediment bowl. I have also synchronized the carb butterfly with the top of governor and also adjusted the low idle speed and the high idle speed inside the governor.

I did notice when doing the carb a date stamp of 3-57 on the top flange. And the carb is white not the red. But the number for the carb matches the 300 u

In advance thanks for any help or suggestions

Karl

Anyways... I am at wits end with it. I can"t get any more revs out of it than 1500. I have rebuilt the carb new gas filter new plugs cleaned the gas tank and sediment bowl. I have also synchronized the carb butterfly with the top of governor and also adjusted the low idle speed and the high idle speed inside the governor.

I did notice when doing the carb a date stamp of 3-57 on the top flange. And the carb is white not the red. But the number for the carb matches the 300 u

In advance thanks for any help or suggestions

Karl