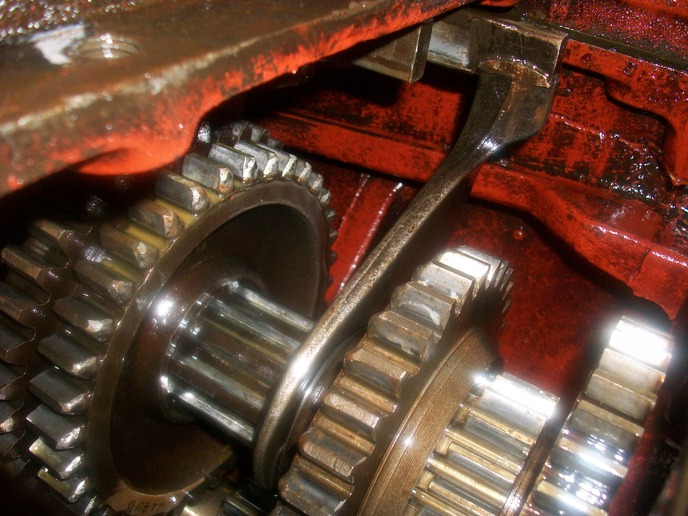

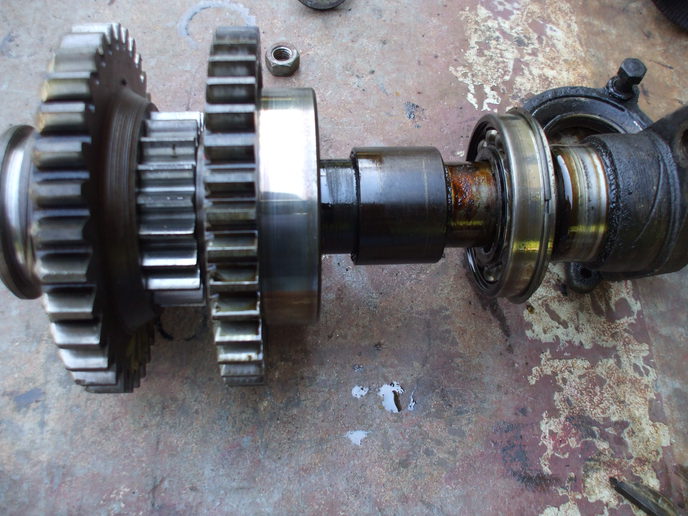

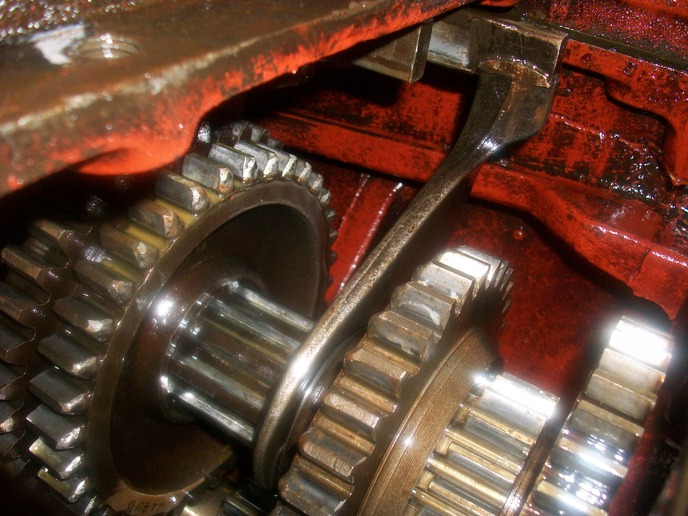

Here is the 4/5 gear, one corner seems to be rounded. With it in 5th gear it doesn't seem to engage the drive shaft completely, you can see about an 1/8to 1/4" gap that seems to be picked up my the shifter when I pull back on it but as soon as I let it go the gear slides out a little and I imagine this is when it jumps out of gear.

My question, does it look like my problem is the gear (the gear does have some slight left to right movement, very little but movement none the less) or is it in the shifter?

My question, does it look like my problem is the gear (the gear does have some slight left to right movement, very little but movement none the less) or is it in the shifter?