Finally connected alternator to the electrical circuit on my Super A. No ballast resistor since using 12v coil.

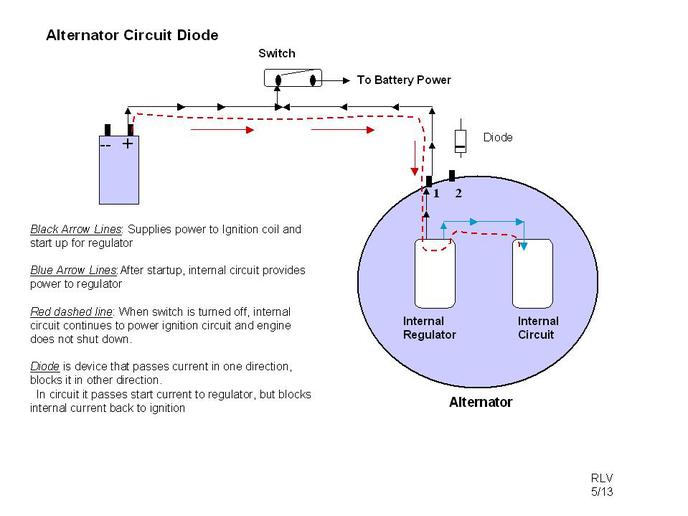

She fires up fine with ignition switch on, charges at about 14.2; then keeps running after pushing the ignition switch off. I disconnected wire from coil to distr to get her to shut down.

She won't start with switch OFF.

I have NOT yet added an idiot light or 15 ohm resistor to the circuit.

She starts and stops fine with the wire disconnected from spade 1 on alternator. But she doesn't charge.

Your comments???? Thanks.

She fires up fine with ignition switch on, charges at about 14.2; then keeps running after pushing the ignition switch off. I disconnected wire from coil to distr to get her to shut down.

She won't start with switch OFF.

I have NOT yet added an idiot light or 15 ohm resistor to the circuit.

She starts and stops fine with the wire disconnected from spade 1 on alternator. But she doesn't charge.

Your comments???? Thanks.