This has been a pain in my side for a while...

Back in June I had installed a rebuilt T/A and a new clutch in a new to me Farmall 350. When the pressure plate was bolted down the springs were coil bound. There was no room for the pressure plate to lift. The T/A wouldn"t work and since the T/A clutch wouldn"t release the shift lever would jam in gear if there was any load on the tractor.

The rear housing had been replaced. Back then D Slater wrote (The rear)"Housing shouldn"t make a difference. Could be a problem with the linkage or release shaft if some parts were mixed with a 300. Is this a farmall or utility.

Pretty sure you have something wrong with the T/A clutch though. You say the springs are completly compressed, or is the fingers all the way in. With a cleaned up and good shape clutch carrier it pays to check the clutch before installing. With the carrier out of the tractor, new clutch plate and the parts bolted in carrier and on a flat surface the fingers should measure near 3.75 from flat surface to finger tips. Hey left a 3 out, adjust finger height to 3.375."

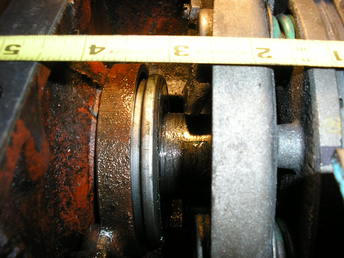

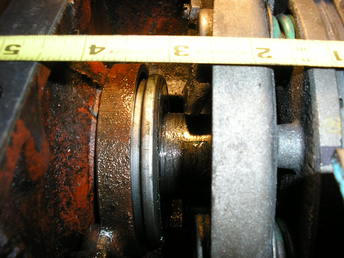

The distance from the back of the T/A flywheel to the tips of fingers is 2 3/4" . With the T/A T/O bearing pushed all the way back against the front wall of the housing the distance from the bearing to the back of the pressure plate is 3.375".

The clutch housing is part no. 360 486 R5. The parts book calls for housing 368 479 R1. Is this housing ( 360 486 R5) compatable with this tractor ?

Thanks

Greg

Back in June I had installed a rebuilt T/A and a new clutch in a new to me Farmall 350. When the pressure plate was bolted down the springs were coil bound. There was no room for the pressure plate to lift. The T/A wouldn"t work and since the T/A clutch wouldn"t release the shift lever would jam in gear if there was any load on the tractor.

The rear housing had been replaced. Back then D Slater wrote (The rear)"Housing shouldn"t make a difference. Could be a problem with the linkage or release shaft if some parts were mixed with a 300. Is this a farmall or utility.

Pretty sure you have something wrong with the T/A clutch though. You say the springs are completly compressed, or is the fingers all the way in. With a cleaned up and good shape clutch carrier it pays to check the clutch before installing. With the carrier out of the tractor, new clutch plate and the parts bolted in carrier and on a flat surface the fingers should measure near 3.75 from flat surface to finger tips. Hey left a 3 out, adjust finger height to 3.375."

The distance from the back of the T/A flywheel to the tips of fingers is 2 3/4" . With the T/A T/O bearing pushed all the way back against the front wall of the housing the distance from the bearing to the back of the pressure plate is 3.375".

The clutch housing is part no. 360 486 R5. The parts book calls for housing 368 479 R1. Is this housing ( 360 486 R5) compatable with this tractor ?

Thanks

Greg