Zachary Hoyt

Well-known Member

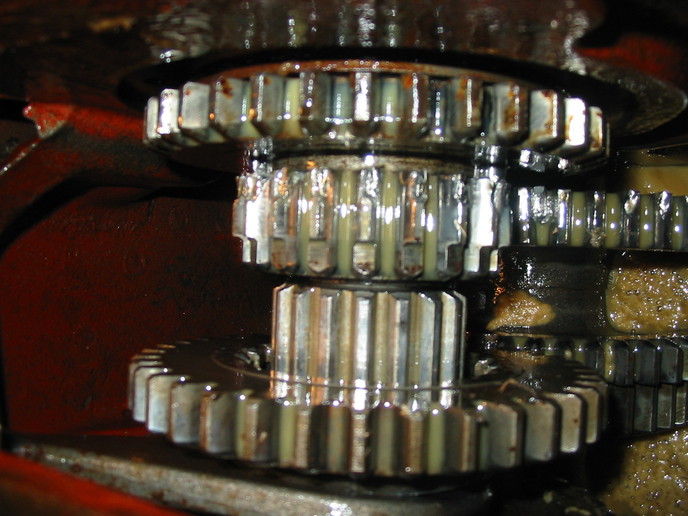

I was plowing snow again today with the 300 and had been out about 10 minutes when I heard several clunks and stepped on the clutch. I was not able to let up on the clutch without killing the engine. The engine runs normally with the pedal down. The IPTO works normally. When I shut the tractor down and blocked the clutch I was able to push the tractor ahead a few feet with the transmission in neutral and everything was normal. The transmission shifts through all gears normally. I took the cover off the TA clutch and looked in there. With the clutch pedal blocked I could rotate the TA in one direction but the TA clutch disk did not move. With the clutch pedal back I could not rotate the TA by hand in either direction. With the pedal blocked I put the tractor in 1st gear and rocked it back and forth, when the TA flywheel turned one way the clutch disk would turn the other way. I removed the clutch inspection cover and everything looked normal. I am wondering if I have a ramp/rollers problem or some other kind of TA problem and if there is anything I can try short of double splitting the tractor again. I had it apart in the summer and can do it again but of course I would rather not if it could be helped. Any advice will be very much appreciated.

Zach

Zach