SweetFeet

Well-known Member

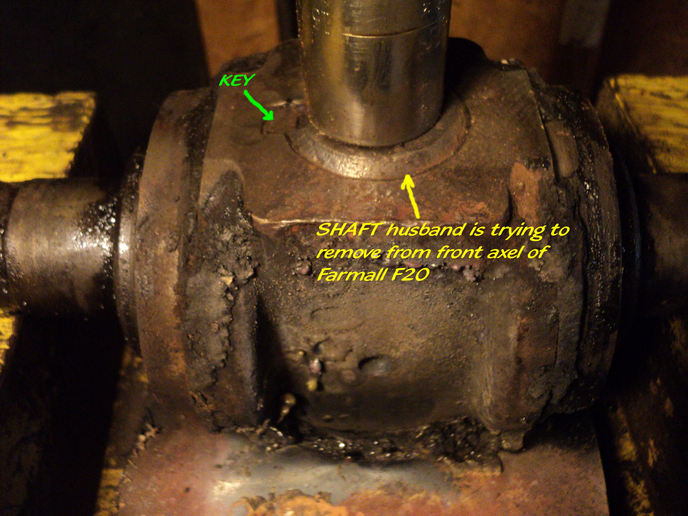

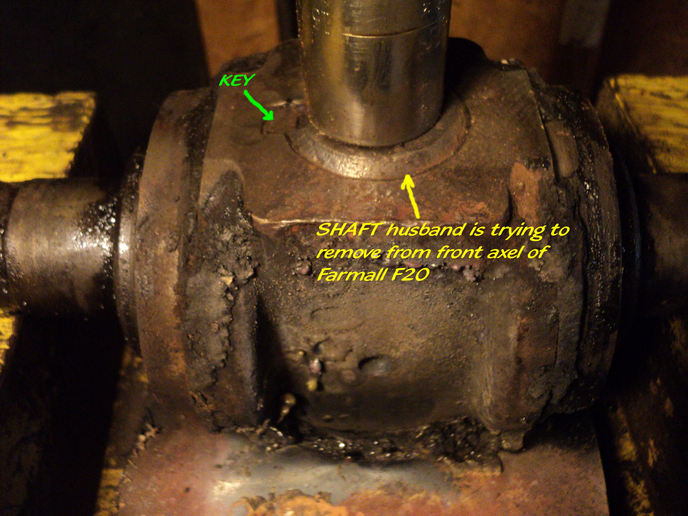

Need to remove the shaft from front axel of a Farmall F20 (going to put the axel on our Regular as it has bad threads).

ANY OTHER TRICKS TO GETTING IT OUT? *Nebraska Kirk already told us he has it upside down -- so was trying to press it IN rather than OUT... so he will flip it and try it the other way after church.

1. Is it a straight key or a halfmoon key that holds the axel straight on the shaft?

2. Anybody with experience in doing this have a better method? Or does he just need to buy a 30 ton jack to put in his press-frame?

Thanks so much if you can help!

ANY OTHER TRICKS TO GETTING IT OUT? *Nebraska Kirk already told us he has it upside down -- so was trying to press it IN rather than OUT... so he will flip it and try it the other way after church.

1. Is it a straight key or a halfmoon key that holds the axel straight on the shaft?

2. Anybody with experience in doing this have a better method? Or does he just need to buy a 30 ton jack to put in his press-frame?

Thanks so much if you can help!