Zachary Hoyt

Well-known Member

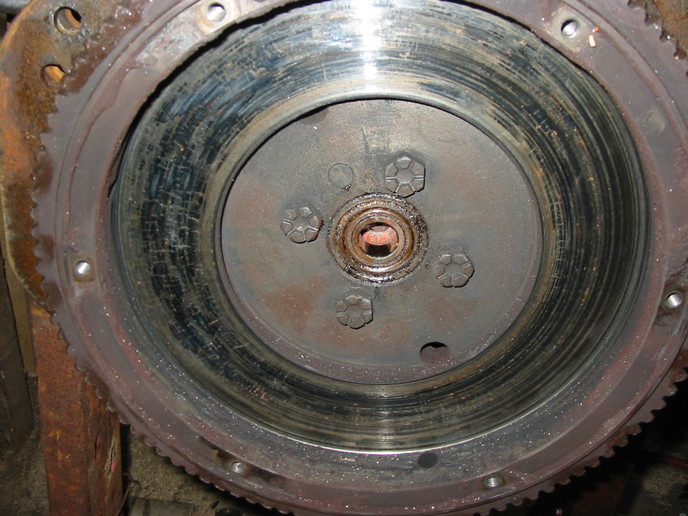

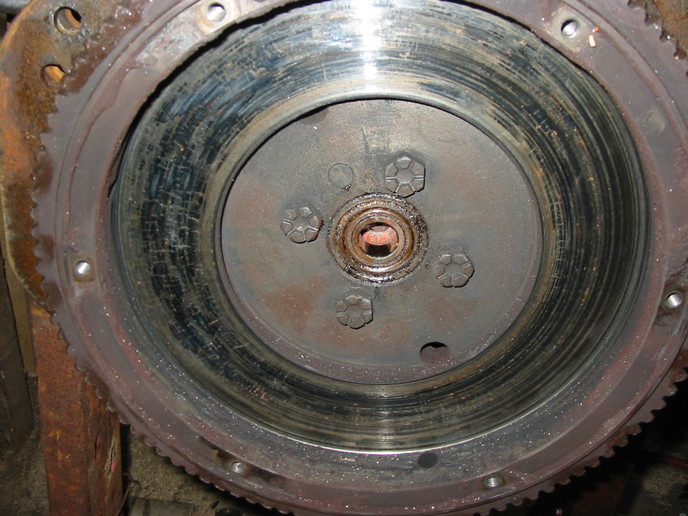

I took the rest of the TA assembly out of the tractor tonight. I checked Kevin Meier's measurements the back end is 2.873 according to my caliper. I didn't have deep enough jaws to get a definite reading on the seal area but it is very smooth with no visible or feelable wear. The rollers look like new, I do not understand the ramp yet so I am not sure if it is worn or not. my I&T manual is on the way. The TA clutch looks like it has never been disengaged, there seems to be no wear on it but it is rusty. A neighbor told me I could clean up the rust on the disk, flywheel and pressure plate with sandpaper moving in small circles and progressing to finer grits. I am wondering also about the engine flywheel and whether it needs to be surfaced or replaced or if it is okay to use as it is. I will be replacing the clutch disk and pressure plate. As always, and advice is much appreciated. I hope to have this project actually get to the reassembly stage soon, seems like I have been taking things apart for a while now.

Zach

Zach