Zachary Hoyt

Well-known Member

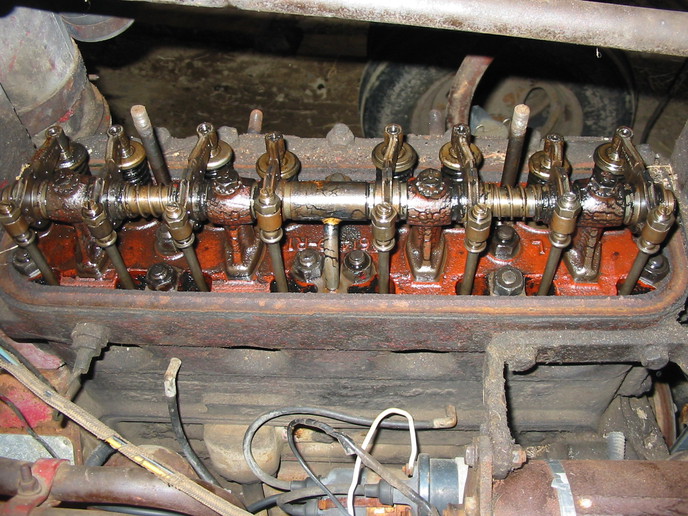

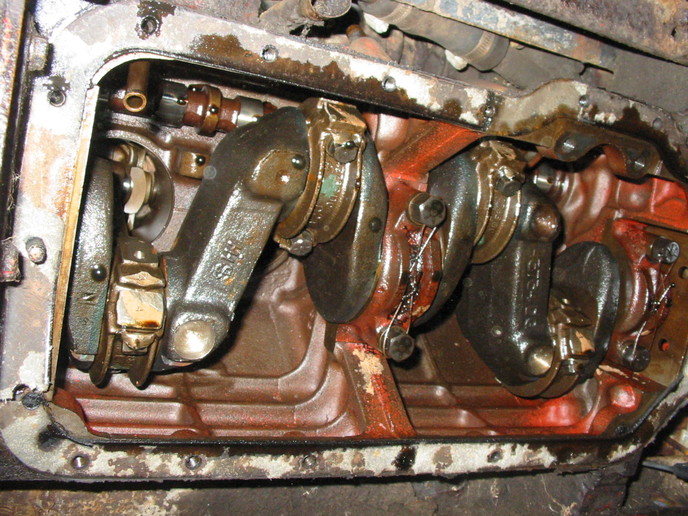

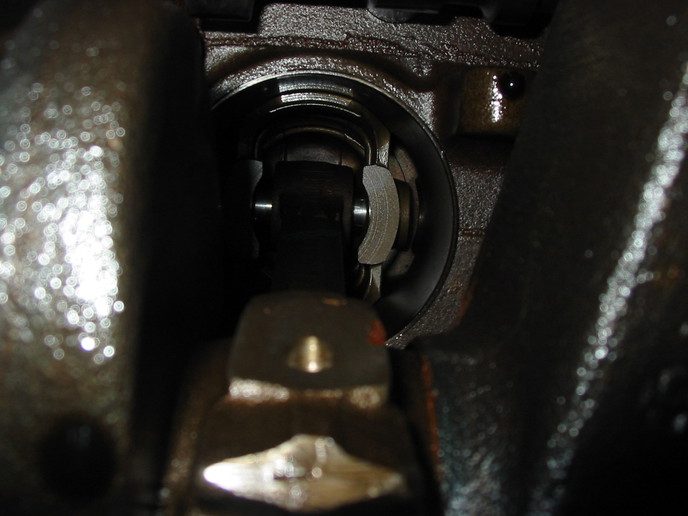

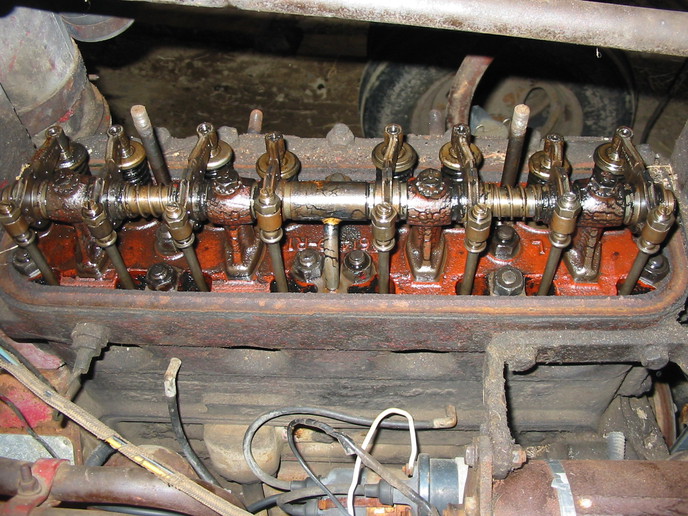

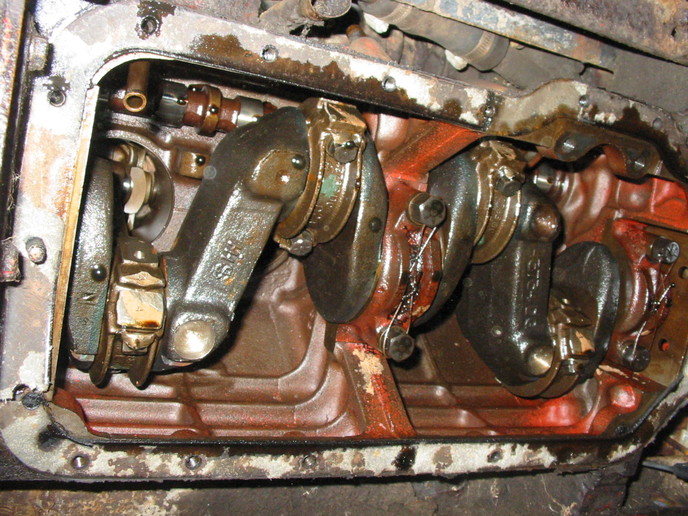

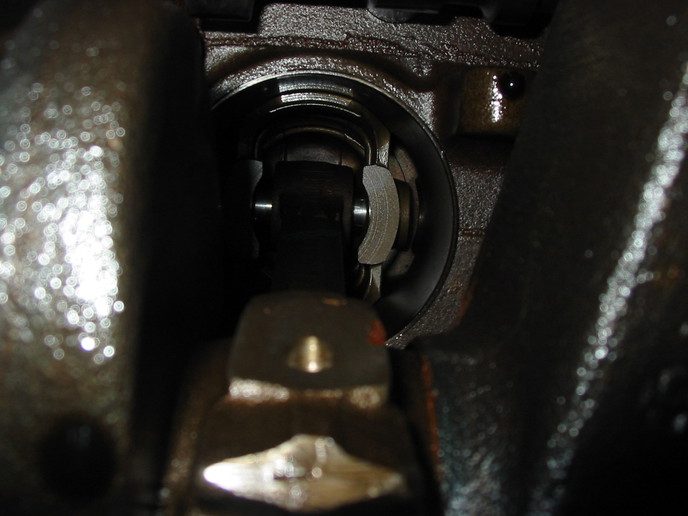

I put the 300 in the shed this afternoon and did some investigating. I pulled the starter and was able to make the flywheel wiggle about 1/16" back and forth with a pry bar on the ring gear. The starter has one ear that is partially broken off, is that repairable or should I be looking for a replacement? I pulled the oil pan and was pleasantly surprised by how clean the inside of the block and the pan were. The insides of the sleeves also look clean. I pulled the valve cover and the valves looked clean too, so I set the cover back on to keep dust out. I removed the manifold since the pipe had several wasp nests in it, and while I found a lot of ladybugs and wasp nests in it I was surprised by how little rust there was. The clutch seems to be stuck, the pedal and linkage move freely but the tractor does not roll while in gear even with the pedal down. I am wondering what to do now. I could drain the coolant and pull the head to see if the rings are stuck to the cylinder walls, or i could check the main and some of the rod bearings to see if they are spun and have made it stick, or I could remove the hydraulic pump, if that is likely to be causing it to stick. The PO said that after a relative had done transmission work on it for him it ran for a while but then began to squeal and he drove it to the yard and shut it down and there it sat, so I am also wondering if the IPTO could have a problem that would make the engine not turn. I do not understand how it works in there yet. Any advice as to what to try next will be much appreciated. One more question, should the battery be under the gas tank in a tray, where it was at some point, or should it be in the box under the seat? Thank you very much.

Zach

Zach