CenTex Farmall

Well-known Member

Checking out a 400D for possible purchase. Generally good condition and has been stored out the weather but hasn't run in 2 or 3 years.

The owner and I got it started on gas without more than usual minor issues, but when you switch to diesel it's not putting fuel to the injectors.

I don't have experience with these things other than reading about them.

The fuel is on at the main tank. I cracked the bottom drain on each big filter and no water came out, did that before starting. We get diesel from the filter bleeders and up to the plunger while running on gas. It comes out in a stream so it's under some amount of pressure. At first the pressure gauge on the injector pump didn't show any movement and after several tries of switching it moved a tiny bit. Tried cracking lines at injector 1 and 2 then switching and didn't have any fuel under pressure, just a few drops weeping out.

Could it have lost prime or have something sticking after sitting for a couple of years?

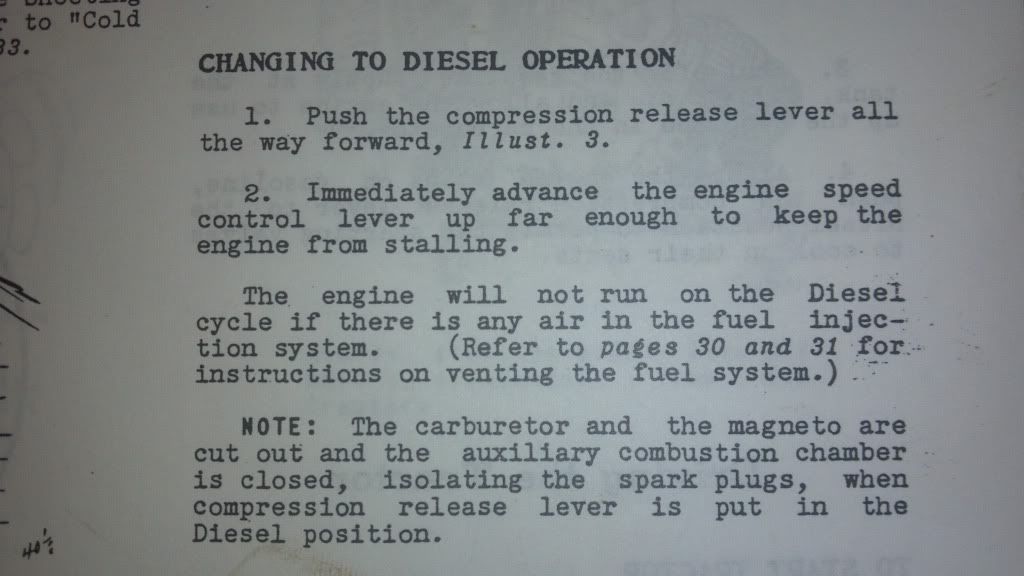

What is the correct procedure for bleeding and priming?

The owner and I got it started on gas without more than usual minor issues, but when you switch to diesel it's not putting fuel to the injectors.

I don't have experience with these things other than reading about them.

The fuel is on at the main tank. I cracked the bottom drain on each big filter and no water came out, did that before starting. We get diesel from the filter bleeders and up to the plunger while running on gas. It comes out in a stream so it's under some amount of pressure. At first the pressure gauge on the injector pump didn't show any movement and after several tries of switching it moved a tiny bit. Tried cracking lines at injector 1 and 2 then switching and didn't have any fuel under pressure, just a few drops weeping out.

Could it have lost prime or have something sticking after sitting for a couple of years?

What is the correct procedure for bleeding and priming?