MaverickM23

Member

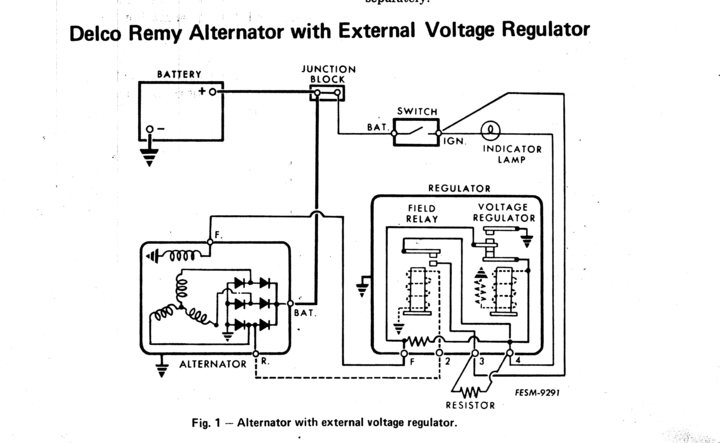

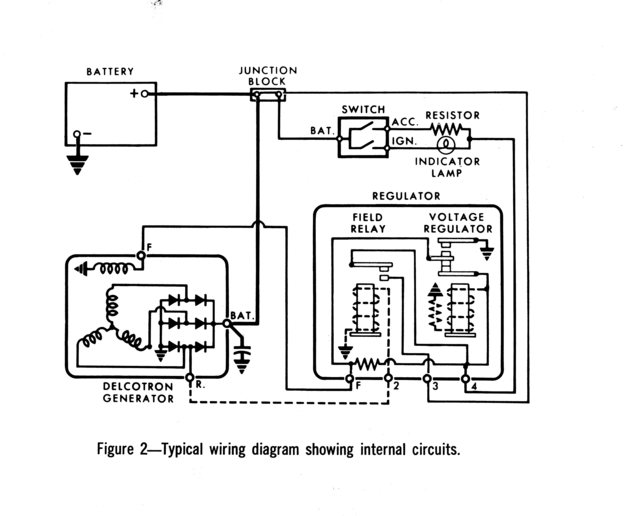

Ok here goes. Im a JD guy but my brother just bought a Farmall 1456. It"s in pretty good shape very straight but needs a little TLC. I am in the process of helping him rewire it. I have ordered wiring harnesses and begun tracing wires, so are not connected and most are cracked and frayed. Before we started the alternator was not charging at all. It is an internally regulated alternator because the voltage regulator has been removed. My question is what do I do with the wires that go to the voltage regulator and resistor? Currently they just had them unplugged and hanging there. If it doesn"t charge after new wiring I will be getting a new alternator but I want to do the wiring right and need to know if they need removed or spliced or whatever. Thanks for any help you can give