Guys, Hauled home the other day a 1966 656 LP! Ser# 15886 just inside the 1966 break line.

So far in my inspections of it the engine is not stuck. But the oil is as nasty black as any Dsl Tractor. Plugs 4-5-6 look ok but neglected for a long time, 1-2-3 were carboned up to the point I do not see how the tractor ran, supposedly 3 yrs ago.

I am covering all based here. But operating under the premise that the valve guide seal crapped out and let excessive oil through, thus the cause for the plug electrodes totally encased in carbon and burnt oil. I suspicion that the head need reworking first!

But IF the rings went bad and There Is Where the problem is......???????????

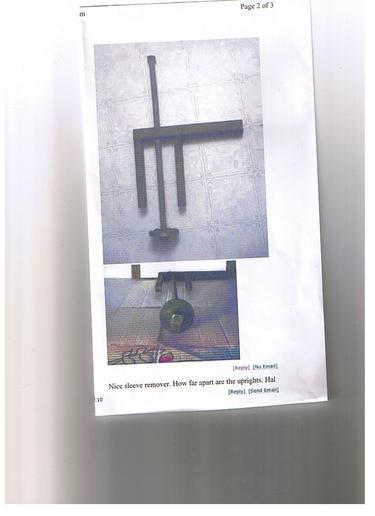

#1 How is the best way to get the sleeves out & not destroy them just in-case a couple are salvageable for another project or someone else might need one.

#2 What is the ID of the bore on the block that the sleeve goes into?? If I have to have a step-plate (hockey puck with a lip) made to pull the sleeve out with. OR is there a place to buy one or just what? This is my first 263 rebuild, though I have done others but not 263 before.

#3 OK!,,, Thoughts, Processes, How have You done it /or How do You do it?!!!

Later,

John A.

So far in my inspections of it the engine is not stuck. But the oil is as nasty black as any Dsl Tractor. Plugs 4-5-6 look ok but neglected for a long time, 1-2-3 were carboned up to the point I do not see how the tractor ran, supposedly 3 yrs ago.

I am covering all based here. But operating under the premise that the valve guide seal crapped out and let excessive oil through, thus the cause for the plug electrodes totally encased in carbon and burnt oil. I suspicion that the head need reworking first!

But IF the rings went bad and There Is Where the problem is......???????????

#1 How is the best way to get the sleeves out & not destroy them just in-case a couple are salvageable for another project or someone else might need one.

#2 What is the ID of the bore on the block that the sleeve goes into?? If I have to have a step-plate (hockey puck with a lip) made to pull the sleeve out with. OR is there a place to buy one or just what? This is my first 263 rebuild, though I have done others but not 263 before.

#3 OK!,,, Thoughts, Processes, How have You done it /or How do You do it?!!!

Later,

John A.