On the IH rake I've been working on - 4 bar enclosed gear.

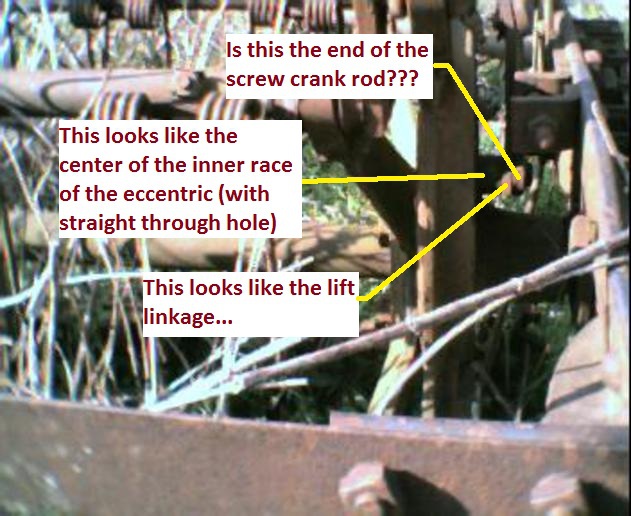

at the gear end of the main reel, there's the big cast "eccentric" - with an outer raceway and inner raceway.

on the inner raceway, there's the main bearing where the reel's main shaft goes through.

On that same cast part, there a small hole in center of the whole part. I BELIEVE that's where the linkage from the lifting lever mounts - on a pin or bolt through that hole.

BUT - What does the end of the screw crank (for adjusting the pitch of the teeth) mount to???

The manual is very unclear on this.

Does it mount to the same hole in the eccentric that the lift linkage attaches to?

Or am I missing a part???

I know pictures would make this a lot easier but I of course can't find my )#(*$# camera right now!!

I do have one picture of what I'm calling the inner race of the eccentric. The small hole in the middle is the one I think the lifting linkage goes to.

In the manual there's a picture that makes it look like I'm missing a part that the crew crank attaches to (#3 in image number 9 if you happen to have the same manual)

But it's very hard to make anything out in that illustration.

My parts rake is a three bar - and it's VERY different in that area.

Thanks,

Jon

at the gear end of the main reel, there's the big cast "eccentric" - with an outer raceway and inner raceway.

on the inner raceway, there's the main bearing where the reel's main shaft goes through.

On that same cast part, there a small hole in center of the whole part. I BELIEVE that's where the linkage from the lifting lever mounts - on a pin or bolt through that hole.

BUT - What does the end of the screw crank (for adjusting the pitch of the teeth) mount to???

The manual is very unclear on this.

Does it mount to the same hole in the eccentric that the lift linkage attaches to?

Or am I missing a part???

I know pictures would make this a lot easier but I of course can't find my )#(*$# camera right now!!

I do have one picture of what I'm calling the inner race of the eccentric. The small hole in the middle is the one I think the lifting linkage goes to.

In the manual there's a picture that makes it look like I'm missing a part that the crew crank attaches to (#3 in image number 9 if you happen to have the same manual)

But it's very hard to make anything out in that illustration.

My parts rake is a three bar - and it's VERY different in that area.

Thanks,

Jon