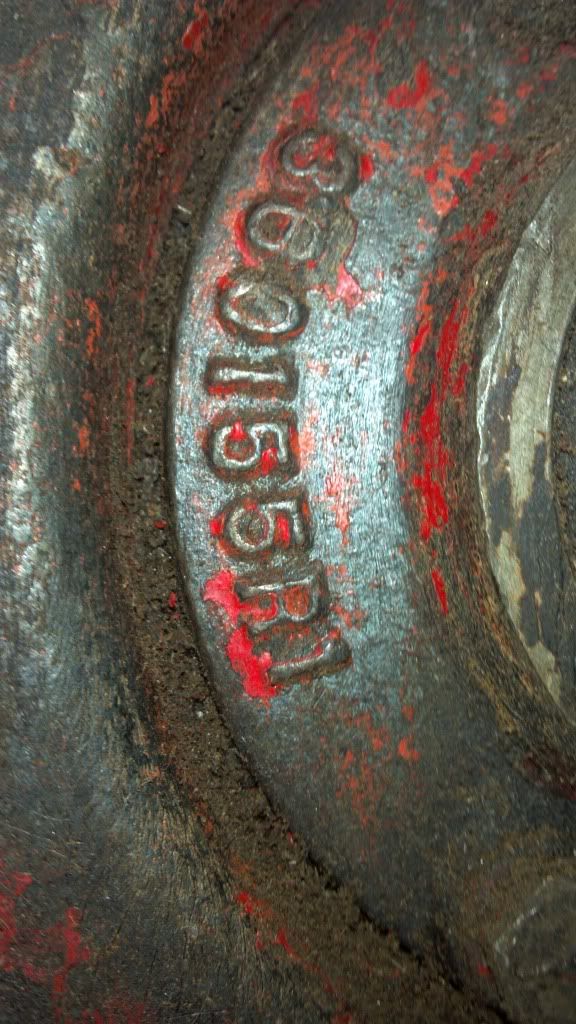

Are the ptos from a SMTA and a 300/350/400/450 EXACTLY the same? We are talking to the point of casting codes (that I didn't see) and the PN cast into the thing around the PTO. (the only pn identifier I saw) It looks like a royal pain to take apart an IPTO and I would really like to just stick the 350 PTO into my SMTA. If there are any external differences I will probably take the good guts from the 350 and put them in the SMTA.

The back story. You can skip this because it is not important to the post but it is why I am looking into this.

I am guessing the reactor bands failed since it worked in the past and then died on the dyno. Then the bands were tightened and it will spin until you put a load on it. I know there could be sheared stuff in there, but the oil looks good. It seems to act like a slipping clutch and the reactor bands are all I see that could act like that.

There is a IPTO from one of those tractors for sale locally. For some reason I think he said it was out of a 300 series, but I am not positive. I would like to at least slide it in there and check the SMTA and "new" IPTO for function. How big of a PITA is that 3' long shaft to get lined up without pulling the lid. That part scares me.

The back story. You can skip this because it is not important to the post but it is why I am looking into this.

I am guessing the reactor bands failed since it worked in the past and then died on the dyno. Then the bands were tightened and it will spin until you put a load on it. I know there could be sheared stuff in there, but the oil looks good. It seems to act like a slipping clutch and the reactor bands are all I see that could act like that.

There is a IPTO from one of those tractors for sale locally. For some reason I think he said it was out of a 300 series, but I am not positive. I would like to at least slide it in there and check the SMTA and "new" IPTO for function. How big of a PITA is that 3' long shaft to get lined up without pulling the lid. That part scares me.