BoonvilleKid

Member

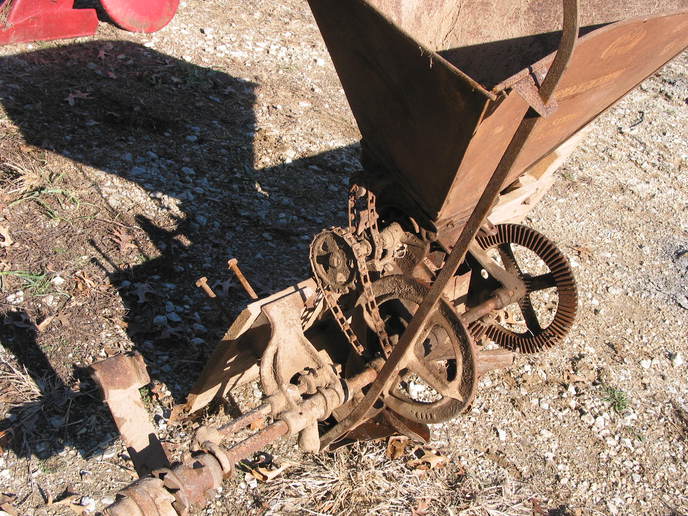

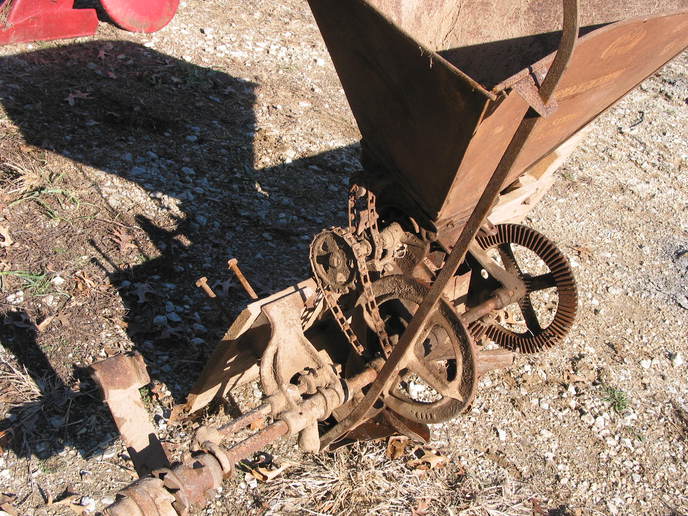

Found a heavy piece of equipment over in the corner of the barn of a newly acquired property. After I got it out in the light I discovered that it was not just a piece of junk but a workable piece of equipment. Have never seen anything like this used but it indicates that it is a "wagonbed seeder". Everything seems to move freely. It has the chain attached, which I assume was driven from a gear on the seed wagon? I hate to take something with the logo McCormick-Deering painted on the side to the iron recycle center so it can end up in China, but I suppose that is what is going to happen to it.