Guys,

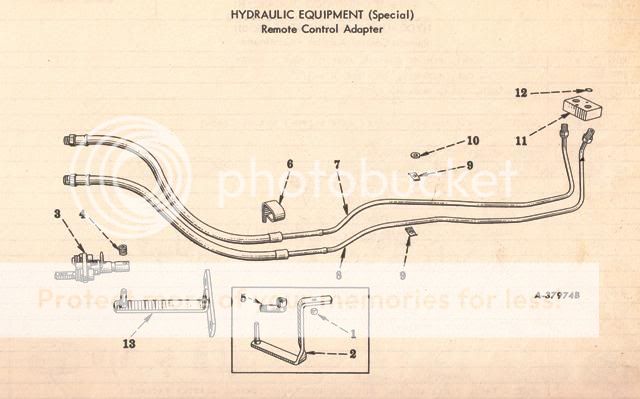

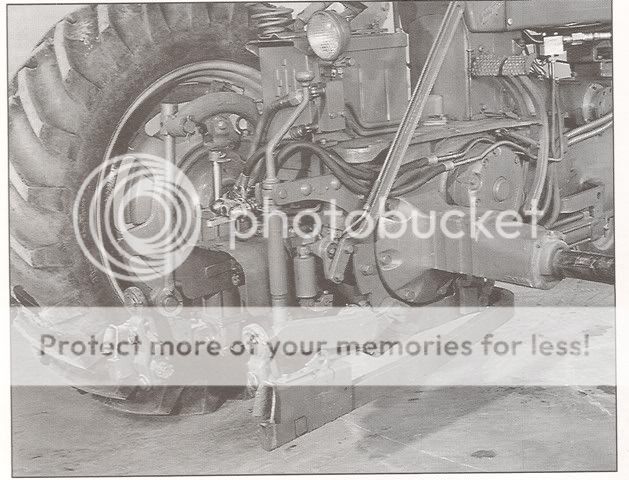

I"m wondering how and where the break-away coupler for rear implement cylinder was attached to the back of an F350 tractor with a fast hitch? Also, the hydraulic ports attached to the battery box connect to the fast hitch cylinder, so I"m assuming the break-away coupler hoses are feed from the hydraulic ports below the gas tank, but which side? How were the hoses originally routed back to the coupler? Where the hoses rubber or steel? Ideally, if someone had an original setup still in place, could you post some pictures of the break-away coupler mounting and the hose routing? Thanks for the help!

I"m wondering how and where the break-away coupler for rear implement cylinder was attached to the back of an F350 tractor with a fast hitch? Also, the hydraulic ports attached to the battery box connect to the fast hitch cylinder, so I"m assuming the break-away coupler hoses are feed from the hydraulic ports below the gas tank, but which side? How were the hoses originally routed back to the coupler? Where the hoses rubber or steel? Ideally, if someone had an original setup still in place, could you post some pictures of the break-away coupler mounting and the hose routing? Thanks for the help!