Zachary Hoyt

Well-known Member

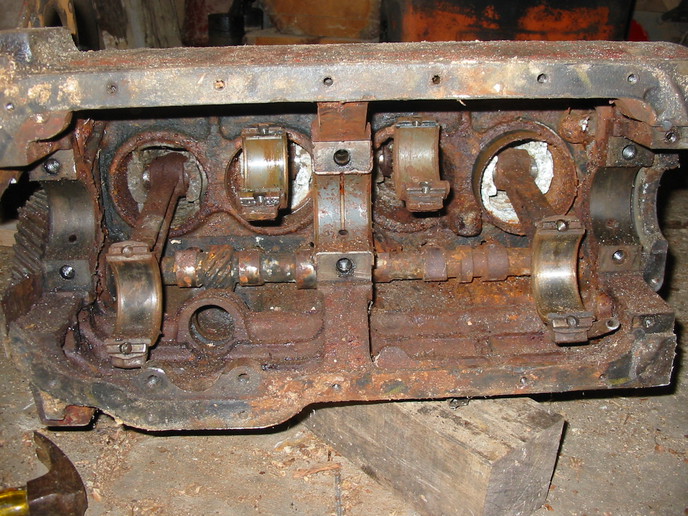

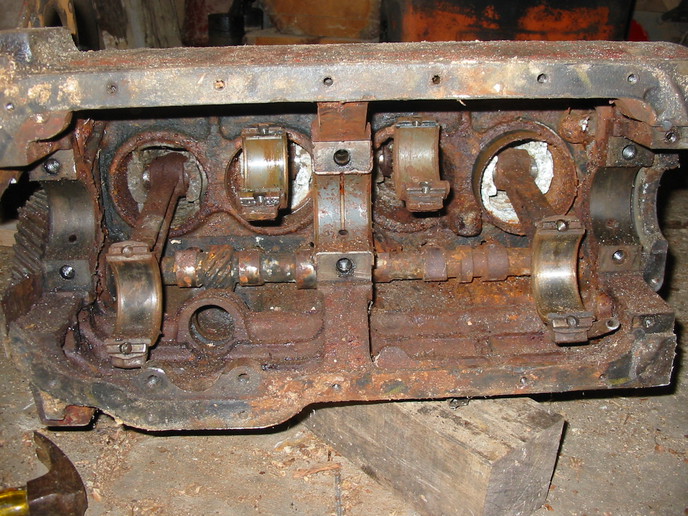

This is a C164 engine out of a 53 Super H. I finally got pistons 1 and 4 to move and was able to get the crank out. This is by far the worst engine I have ever been inside. The sleeves are partially falling apart, and I am wondering if I should try to save the pistons or if I should assume they are probably no good. I would like to save the cam gear as it is in good shape but the camshaft is rusted in place and won't turn to allow me to remove the bolts. Is there a way to get the gear off without chipping the teeth, with the camshaft still in there? At this point I am considering three options: scrap the whole mess, try to remove the pistons and sleeves and cam by any means necessary and save the block or try to take it apart while not damaging any of the remaining parts. Any advice will be much appreciated.

Zach

Zach