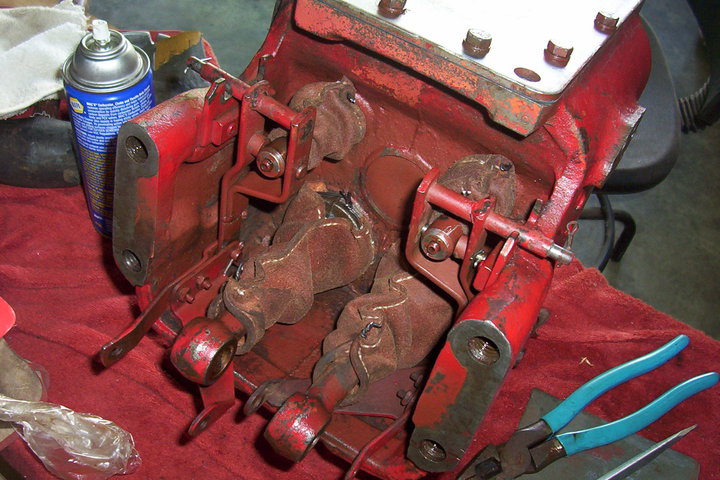

The only major component left attached to the Super A right now is the touch control unit.

I've been sort of ignoring it for a while. Looks like a whole lotta screws holding it together, and I imagine it's full of a whole lotta springs and ball bearings and seals, etc.

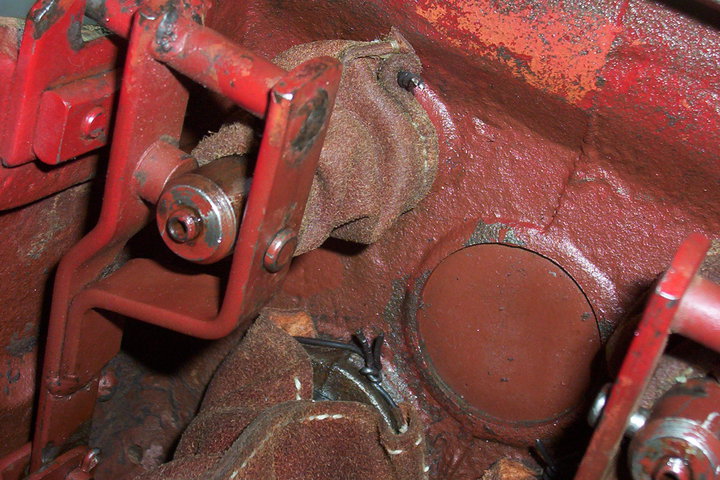

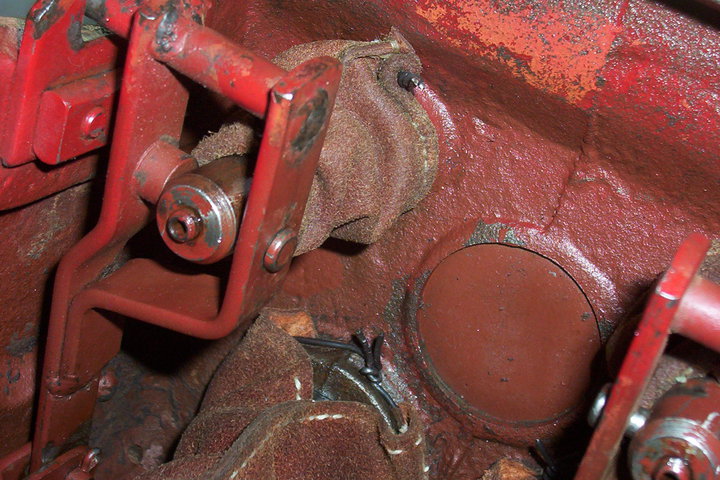

The hydraulics DO work on the tractor, but they're not 100%. They're not exactly smooth. And there's obviously fluid leaking from somewhere "inside" where the rockshafts attach.

I'm toying with the idea of re-building the unit with the 4H kids... but I'm afraid that one little "oops" and I'll be living without hydraulics.

(My super A won't be so super any more)

I found a gasket/seal rebuild kit, and was thinking about ordering it - it aint cheap.

Anybody have any experience with these? Should I just leave well enough alone? As I said, it does work - just not perfectly... And I could live with a minor leak or two...

Would like to hear other's experiences here. Is it brain surgery? or is it simply take stuff out and put it back where you found it?

I picture removing the cover and watching ballbearings and springs go flying everywhere.

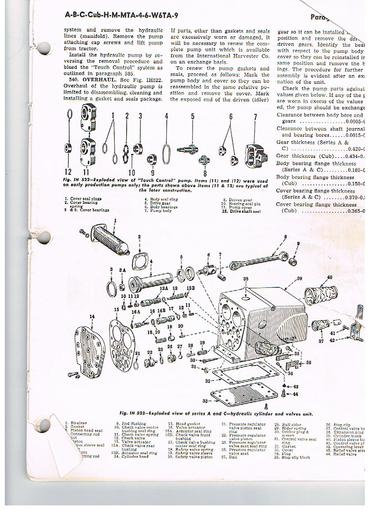

Is there any kind of service manual specifically geared towards rebuilding one of these things?

And advice would be appreciated.

I've been sort of ignoring it for a while. Looks like a whole lotta screws holding it together, and I imagine it's full of a whole lotta springs and ball bearings and seals, etc.

The hydraulics DO work on the tractor, but they're not 100%. They're not exactly smooth. And there's obviously fluid leaking from somewhere "inside" where the rockshafts attach.

I'm toying with the idea of re-building the unit with the 4H kids... but I'm afraid that one little "oops" and I'll be living without hydraulics.

(My super A won't be so super any more)

I found a gasket/seal rebuild kit, and was thinking about ordering it - it aint cheap.

Anybody have any experience with these? Should I just leave well enough alone? As I said, it does work - just not perfectly... And I could live with a minor leak or two...

Would like to hear other's experiences here. Is it brain surgery? or is it simply take stuff out and put it back where you found it?

I picture removing the cover and watching ballbearings and springs go flying everywhere.

Is there any kind of service manual specifically geared towards rebuilding one of these things?

And advice would be appreciated.