jtbartlett

Member

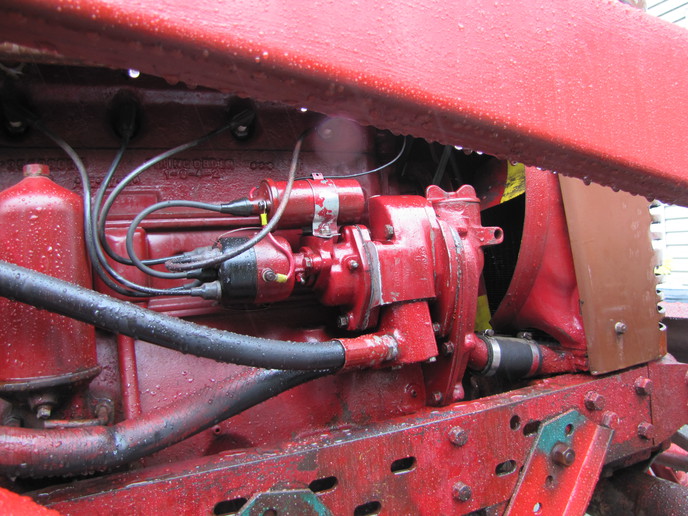

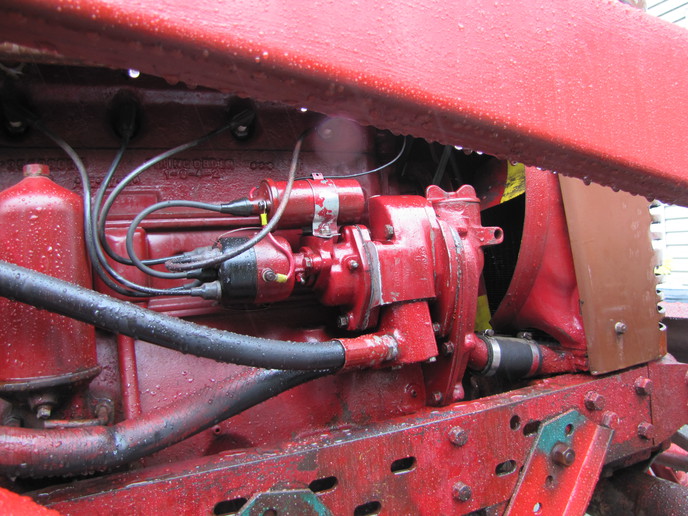

I have been having a seriously difficult time with my super M hydraulics. I have posted before but nothing to date has worked out. Its a "53 stage 2 with a new idea loader and a Saginaw county 3pt hitch, factory live power, no liftall. I have 3 Gresen valves plumbed in. 2 are Gresen 575 2 way valves (for the bucket cylinders and the 3 pt cylinders) and 1 is a Gresen 300 series 1 way valve for the loader arms. Quick connectors are on the bucket and loader lines. I know for sure the pump is pumping. The problem I am having is hydraulic oil blowing out of the filler vent. I can pull the hydraulic valve selector on the resevoir and I get foamy hydraulic oil out of the cap. Not a little oil under load but lots of oil and air under no load. My valves are working ok because I can raise the loader arms, extend the bucket cylinders and operate the 3pt. I get a whole lot of oil when the loader is lowered. The cylinders are 1 way with 3/8 vents. I don"t see how air can be getting into the hydraulics. I thought I had a pump blockage but I pulled and examined the pump and installed a filter on the return line to the resevoir. I believe loaders were used on super M"s so I can see how I have a capacity problem. I raised the loader arms until I was short on oil then added more as needed. Same thing with the bucket cylinders. I Believe IH used the filler neck for the hydraulic return as there is no other provision on the resevoir. I also extended the fill neck 6" thinking it might not blow up that high but it still does. I"m all out of ideas on this one. My next move is to replace the suction line to the pump thinking I might be drawing in air but at this point it"s a long shot. Any ideas? Anything would help at this point. Anyone willing to give a phone call it"s 802-626-9041. I"ll repost pictures so you can see what I have going on. I can take more pictures too if there"s something else you need to see.